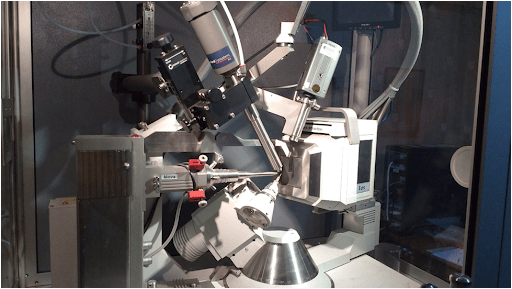

X-ray Diffraction (XRD)

X-ray Diffraction (XRD) is a non-destructive analytical technique used to determine crystalline structure, phase composition, lattice spacing, crystallite size, and degree of crystallinity in materials. When a material is exposed to X-rays, its crystal lattice diffracts the beams in characteristic patterns that serve as a unique structural fingerprint.

At Materials Metric, XRD is applied to identify phases, assess crystallinity, and understand structure–property relationships across metals, ceramics, polymers, pharmaceuticals, battery materials, and advanced composites. Our diffraction workflows deliver reproducible peak profiles and defensible structural data supporting materials development, quality control, failure analysis, and regulatory documentation.

Use of XRD

Researchers and manufacturers use XRD to:

• Identify and quantify crystalline phases

• Measure crystallinity in semi-crystalline polymers

• Detect polymorphs or phase transitions

• Evaluate stress, strain, and lattice abnormalities

• Determine crystallite size using Scherrer analysis

• Characterize thin-film orientation and texture

• Analyze battery electrode structures

Applications of XRD

• Metals & Alloys: grain orientation, phase fractions

• Ceramics & Glass: structural verification, purity

• Polymers: crystallinity, polymer phase transitions

• Battery Materials: cathode/anode phase characterization

• Pharma: polymorph identification and stability studies

• Thin Films & Coatings: texture, orientation, and crystallinity

Sample Analysis Process

1. Sample Submission & Review

- Identify material type (powder, film, pellet, bulk)

• Define phases of interest or analysis goals

2. Sample Preparation

- Powder grinding or mounting

• Thin-film orientation alignment

• Bulk material polishing if needed

3. XRD Measurement

- θ–2θ scans

• High-resolution modes for fine structures

• Optional grazing incidence for thin films

4. Data Processing & Reporting

- Full diffraction pattern

• Phase identification via reference libraries

• Crystallinity and crystallite size

• Clear summary of structural findings

Why Choose Materials Metric for Your XRD Analysis

Materials Metric offers high-resolution XRD services supported by strong expertise in structural characterization. We provide:

- Precise phase identification and quantification

• Crystallinity analysis for polymers and composites

• Thin-film and coating structural evaluation

• Battery material characterization (LCO, NMC, LFP, etc.)

• Clear, annotated diffraction reports for R&D and QC

By combining XRD data with XPS, TEM, ICP, and mechanical or thermal analysis, we help clients understand how structure relates to performance and reliability.