Atomic Force Microscopy (AFM)

Atomic Force Microscopy (AFM) is a high-resolution imaging technique that uses a nanoscale probe to physically scan the surface of a material. As the sharp tip moves across the sample, it measures surface forces, such as van der Waals, electrostatic, or mechanical interactionsto generate 3D topographical maps with sub-nanometer vertical resolution.

Unlike electron microscopy, AFM does not rely on electron beams or vacuum environments, making it ideal for non-conductive, soft, hydrated, or biological samples. AFM can operate in air, liquid, or controlled environments, enabling real-time evaluation of material surfaces, mechanical properties, and nanoscale interactions.

Use of Atomic Force Microscopy

AFM is used to analyze surface topography, nanomechanical properties, and material–probe interactions with unmatched spatial precision.

It enables researchers to:

- Visualize nanoscale textures, roughness, and surface defects

• Measure mechanical properties such as stiffness, elasticity, and adhesion

• Evaluate biomaterials, hydrogels, and polymers in hydrated or ambient conditions

• Study nanoscale wear, friction, and tribology behavior

• Analyze particle aggregation, nanostructures, and thin-film morphology

• Assess cell surfaces, tissue scaffolds, and engineered biomaterials

Applications of AFM

AFM supports a broad range of R&D, product development, and quality-control workflows:

• Polymers & Composites: nanoscale roughness, phase imaging, filler dispersion

• Biomaterials & Hydrogels: elasticity, viscoelasticity, and surface interaction mapping

• Nanomaterials & Thin Films: particle size, film uniformity, nano-pattern integrity

• Medical Devices: surface modifications, coatings, wear analysis

• Electronics & Photonics: micro-/nano-fabrication quality, feature height measurements

• Cell & Biological Samples: membrane texture, adhesion forces, live-cell imaging (in fluid)

Sample Analysis Process

1. Sample Submission & Objective Review

- Client provides material description, imaging goals, and required resolution

• We evaluate sample type (soft polymer, ceramic, biomaterial, nanomaterial, film, etc.)

2. Sample Preparation

Preparation depends on sample stiffness and imaging mode:

• Mounting: attached to AFM disks using adhesive tabs or specialized fixtures

• Cleaning: dust or particulates removed with appropriate gentle methods

• Hydrated samples: placed in fluid cells for liquid imaging

• Soft/biological samples: imaged at low forces to avoid deformation

3. AFM Imaging & Property Mapping

We perform the appropriate AFM mode depending on the material:

• Contact mode: high-resolution topography for stiff materials

• Tapping/Intermittent mode: ideal for soft samples; reduces surface damage

• Phase imaging: maps compositional variations or filler domains

• Force–distance curves: adhesion, elasticity, and modulus calculations

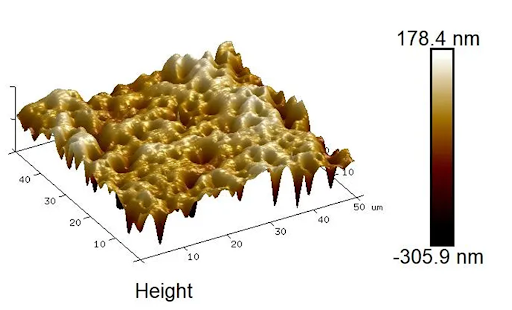

• 3D surface profiling: height, roughness, and morphological quantification

4. Data Processing & Reporting

- 3D topography maps with scale bars and dimensional metadata

• Roughness values (Ra, Rq, Rz) and phase contrast images

• Mechanical property plots (adhesion, stiffness, elasticity)

• Comprehensive, annotated report with interpretations aligned to your objectives

Why Choose Materials Metric for Your AFM Analysis

Materials Metric provides high-resolution AFM imaging and nanomechanical measurementssupported by our expert materials scientists. We ensure your data is scientifically accurate, publication-ready, and fully aligned with your R&D and product development goals.

Our AFM services include:

- 3D nanoscale topography imaging for polymers, biomaterials, thin films, and nanostructures

• Mechanical property mapping (elastic modulus, adhesion, stiffness)

• Phase, amplitude, and force-curve analysis for compositional and surface interaction studies

• Imaging in air or liquid for biological and hydrated materials

• Specialized handling for soft, tacky, or delicate samples

• Clear, annotated reporting with quantitative metrics and expert interpretation

By combining AFM results with our SEM, spectroscopy, mechanical testing, and thermal analysis, Materials Metric helps you establish nanoscale structure, property relationships essential for product refinement and scientific understanding.