Tensile, Compression, and Shear Testing

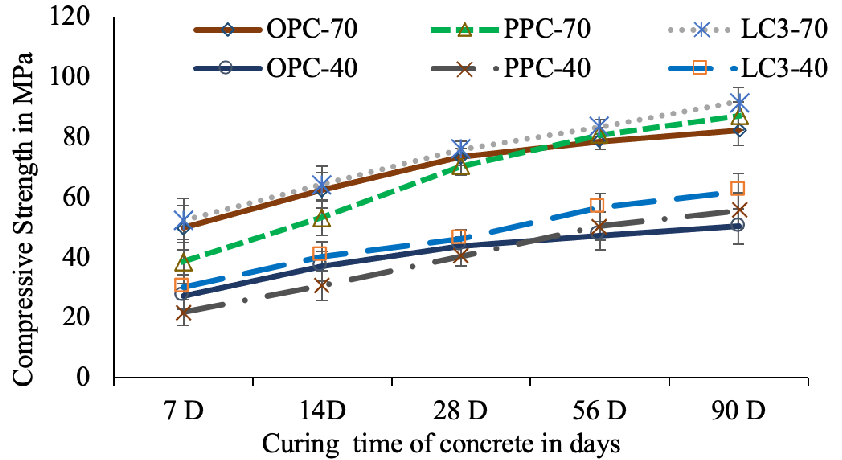

Tensile, compression, and shear testing are fundamental mechanical evaluation methods used to quantify how materials respond to applied forces under controlled conditions. These tests measure critical mechanical properties including tensile strength, Young’s modulus, elongation, compressive strength, shear resistance, and full stress–strain behavior.

At Materials Metric, mechanical testing is performed to assess durability, deformation, and failure modes across polymers, biomaterials, composites, elastomers, and engineered materials. Our workflows support material selection, design validation, quality control, and regulatory evaluation by delivering accurate, reproducible mechanical performance data aligned with real-world loading conditions.

Use of Tensile, Compression, and Shear Testing

These tests are used to:

• Measure stiffness, strength, ductility, and elasticity

• Evaluate deformation and failure under applied loads

• Validate the structural integrity of materials and products

• Compare mechanical performance before and after processing, sterilization, or aging

• Support product development and regulatory submissions

• Ensure compliance with ASTM/ISO mechanical testing standards

Applications

- Polymers & Plastics: modulus, elongation, yield behavior

- Biomaterials: compression of hydrogels, scaffolds, or tissue-like materials

- Adhesives & Sealants: shear strength and bond durability

- Composites: layer integrity and failure modes

- Medical Devices: mechanical strength of sutures, films, tubing, implants

- Metals & Ceramics: tensile and compressive strength characterization

Sample Analysis Process

1. Submission & Objective Review

- Identify testing type (tensile, compression, shear) and performance requirements

- Confirm relevant industry standards (ASTM, ISO)

- Determine whether environmental or temperature-controlled testing is needed

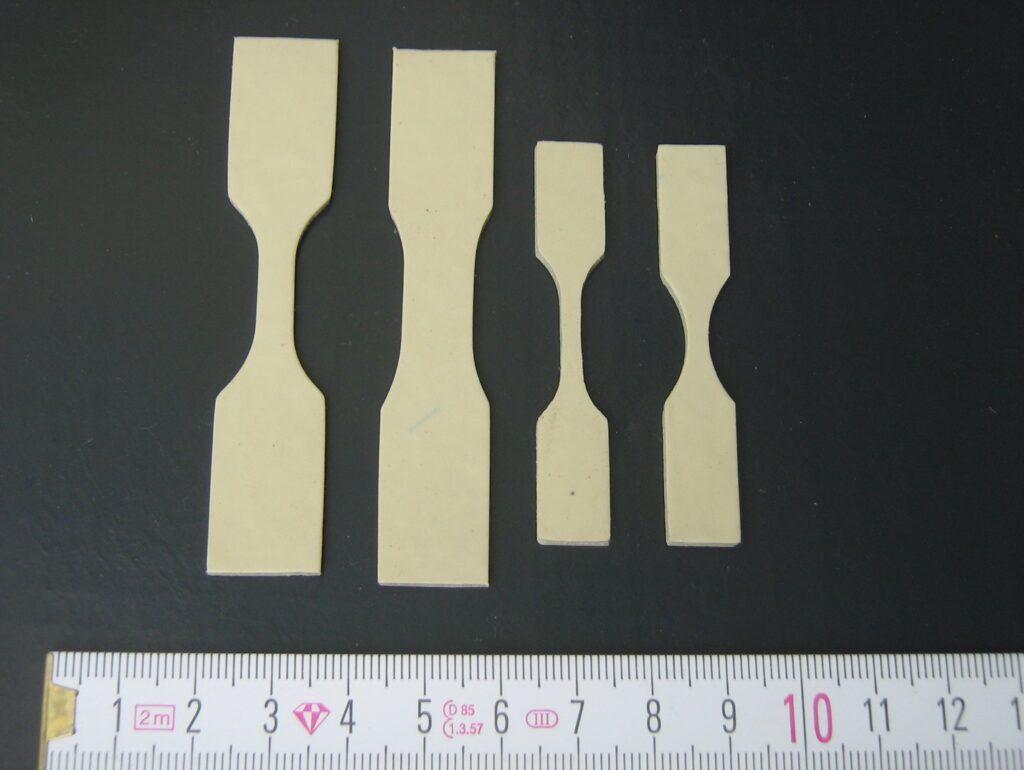

2. Sample Preparation

- Specimens prepared to standardized or custom geometries (dogbone, cylinders, cubes, strips)

- Edges refined to minimize stress concentrations and premature failure

- Adhesive specimens prepared with controlled bond area and thickness

- Hydrated or soft biological samples conditioned appropriately before testing

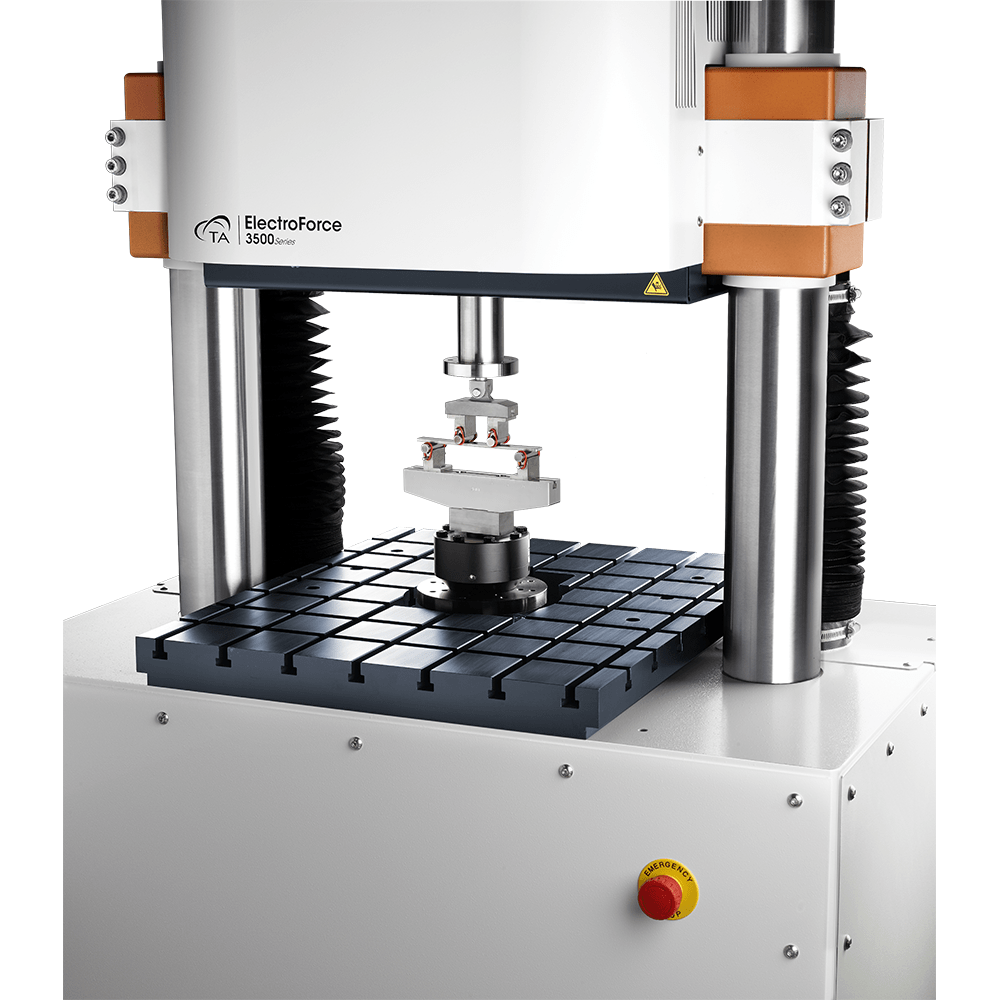

3. Mechanical Testing

- Controlled loading applied at defined strain or displacement rates

- Force and displacement recorded continuously

- Stress–strain curves generated for full mechanical characterization

- Optional temperature, humidity, or environmental conditions applied as required

4. Data Processing & Reporting

- Tensile strength, compressive strength, shear strength

- Young’s modulus, yield stress, elongation, toughness

- Load–displacement and stress–strain curves

- Interpretation connecting results to material performance and design criteria

Why Choose Materials Metric for Mechanical Testing

Materials Metric provides accurate and reliable mechanical testing backed by expertise in polymers, biomaterials, composites, and medical device materials.

Our services offer:

- High-precision tensile, compression, and shear measurements

- Custom fixture design for unique geometries and medical device components

- Testing aligned with ASTM/ISO standards

- Detailed reporting with engineering interpretation and failure mode analysis

- Integration with microscopy, profilometry, and chemical analysis for comprehensive material evaluation

We ensure your materials and products meet their mechanical performance requirements with confidence.