Fatigue & Wear Analysis

Fatigue and wear analysis evaluates how materials and components respond to cyclic loading, repeated contact, friction, abrasion, and contact stress over time. These conditions often govern real-world performance and failure well before ultimate strength limits are reached, making fatigue and tribological behavior critical to durability assessment.

At Materials Metric, fatigue and wear testing is used to assess fatigue resistance, wear mechanisms, surface degradation, and long-term material stability. Our analyses help predict service life, identify dominant failure modes, and optimize material performance under cyclic and tribological conditions relevant to biomedical devices, structural components, coatings, polymers, metals, and composite materials.

Use of Fatigue & Wear Testing

• Determine fatigue life under repeated stress

• Assess wear rate, friction coefficient, and surface degradation

• Identify failure modes under real-use loading

• Compare material performance before/after sterilization, aging, or environmental exposure

• Validate mechanical endurance of implants, devices, and engineering components

• Optimize coatings and surface treatments for improved longevity

Applications

- Medical Devices: stents, orthopedic implants, sutures, tubing

- Polymers & Elastomers: cyclic deformation and abrasion resistance

- Metals & Alloys: fatigue strength and crack propagation

- Coatings & Thin Films: wear durability, friction, delamination

- Composites: interlaminar fatigue and delamination behavior

- Consumer/Industrial Products: long-term reliability assessment

Sample Analysis Process

1. Submission & Goal Definition

- Specify fatigue mode (tension, compression, flexural)

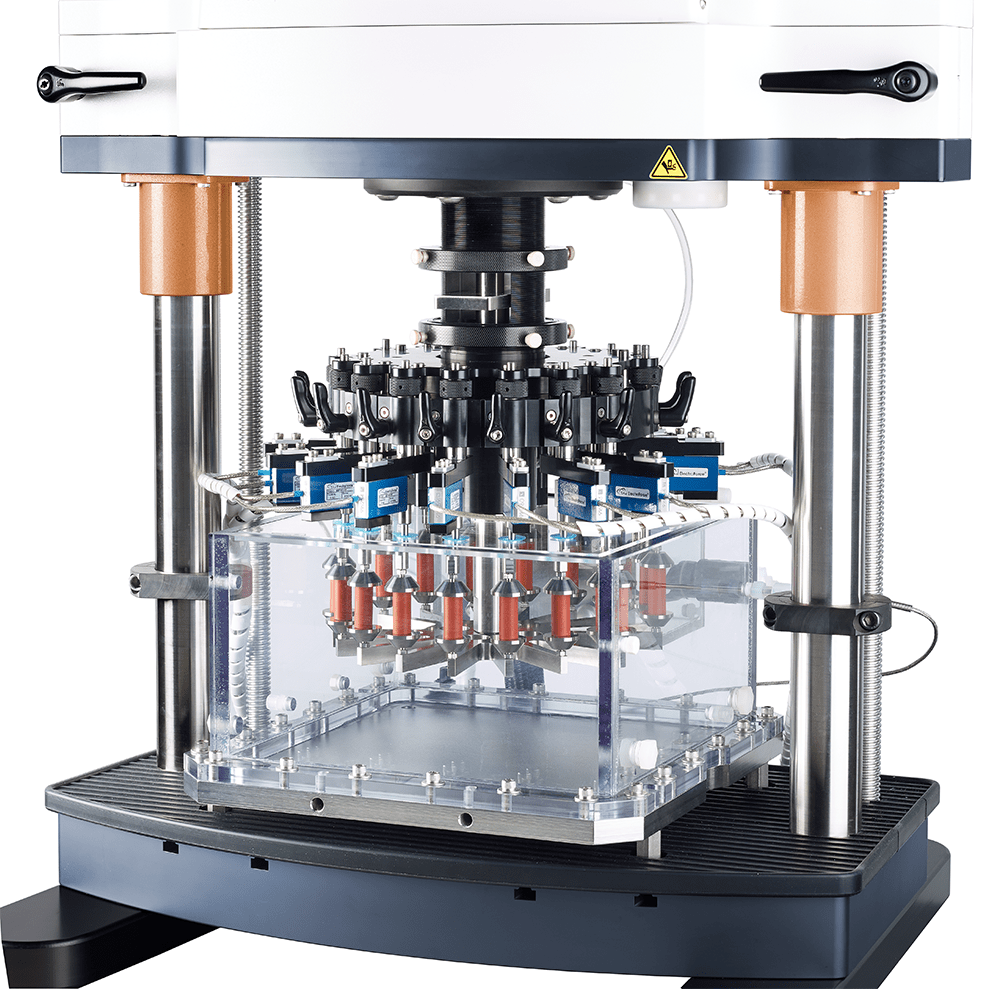

- Define wear mode (pin-on-disk, reciprocating, abrasion, rotational)

- Set load levels, cycle counts, and environmental conditions

2. Sample Preparation

- Specimens shaped according to relevant standards

- Surfaces cleaned and prepared for consistent testing

- Hydrated or soft biomaterials conditioned appropriately

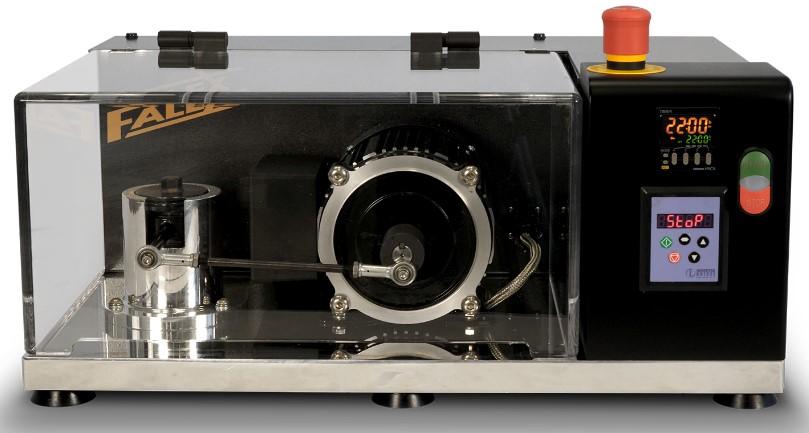

3. Fatigue or Wear Testing

- Controlled cyclic loading for fatigue evaluation

- Friction and wear measurements under defined loads

- Surface condition monitored during and after testing

4. Data Processing & Reporting

- S–N curves and fatigue life estimates

- Wear rate, wear volume, and friction coefficient

- Surface damage characterization (optical or SEM)

- Interpretation linked to reliability and design requirements

Why Choose Materials Metric for Fatigue & Wear Testing

Materials Metric offers accurate and application-focused fatigue and wear testing supported by multidisciplinary expertise.

Our capabilities include:

- High-cycle and low-cycle fatigue testing

- Wear and friction evaluation under realistic loading conditions

- Detailed surface failure analysis using SEM or profilometry

- Testing tailored to polymers, composites, biomaterials, coatings, and metals

- Engineering-level reporting that supports product development and regulatory needs

We provide the insights needed to understand how materials age, degrade, and perform over time.