Surface Roughness & Adhesion Testing

Surface roughness analysis quantifies the micro-scale height variations of a material’s surface, while adhesion testing evaluates how strongly a coating or bonded interface resists mechanical separation. Together, these assessments help determine coating quality, bond performance, wear resistance, and functional surface behavior.

At Materials Metric, we quantify surface texture, roughness parameters, coating adhesion, and interfacial integrity to understand how surface properties affect wear behavior, mechanical stability, coating durability, wettability, and material–tissue or material–material interactions across polymers, metals, ceramics, coatings, and engineered surfaces.

Use of Surface Roughness & Adhesion Testing

These methods are used to:

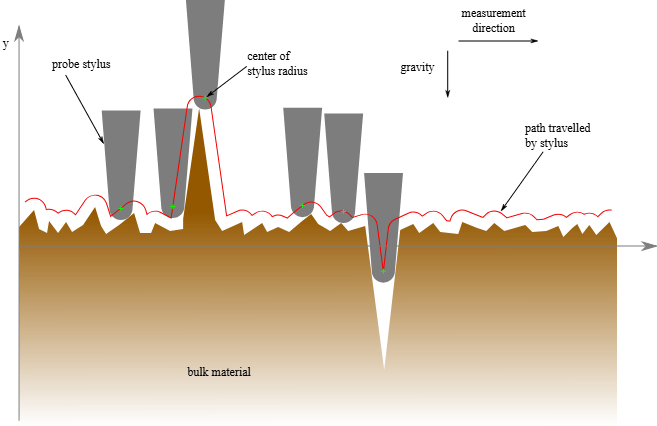

• Measure roughness parameters (Ra, Rq, Rz)

• Characterize surface preparation effectiveness

• Evaluate coating adhesion and interfacial strength

• Identify defects such as delamination, cracking, or weak bonds

• Assess surface finish related to friction, wear, or fluid interaction

• Compare surfaces before and after processing or treatment

Applications

- Coatings & Thin Films: adhesion strength, uniformity

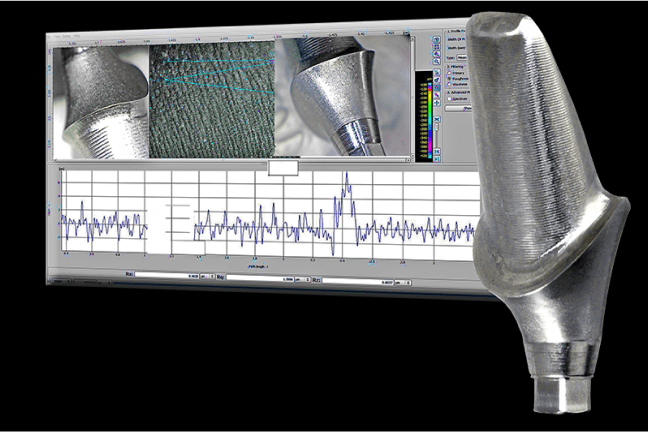

- Medical Devices: implant surfaces, scaffold roughness

- Polymers & Composites: bonding quality and failure modes

- Metals: polishing quality and surface preparation

- Electronics: film uniformity, adhesion reliability

Sample Analysis Process

1. Submission & Goal Definition

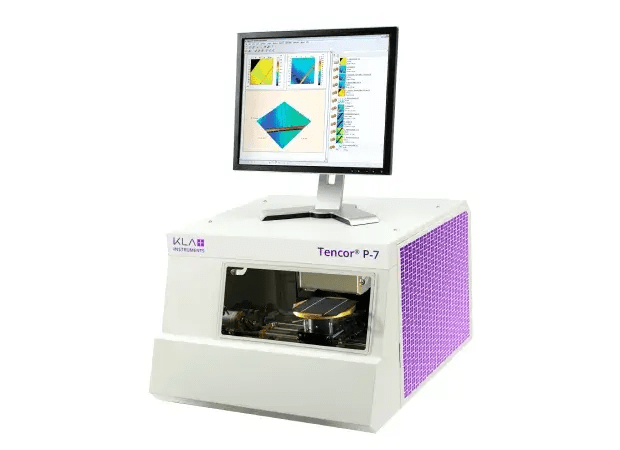

- Specify roughness tests (stylus, optical profilometry, mapping)

- Select adhesion method (scratch test, pull-off, cross-hatch)

- Identify critical surface regions

2. Sample Preparation

- Surfaces lightly cleaned to remove debris or oils

- Coating thickness and geometry verified

- Bonded samples prepared with defined adhesive area

3. Surface or Adhesion Testing

- Roughness measured via stylus or optical profilometry

- Adhesion evaluated using mechanical loading (scratch, pull-off, tape)

- Failure initiation and propagation observed

4. Data Processing & Reporting

- Roughness metrics and surface maps

- Adhesion force, scratch resistance, failure points

- Failure morphology assessment

- Interpretation linked to coating quality and interface strength

Why Choose Materials Metric for Surface Testing

Materials Metric provides high-precision surface characterization tailored to coatings, films, implants, and engineered materials.

Our strengths include:

- Quantitative roughness measurement with 2D and 3D mapping

- Reliable adhesion testing following ASTM/ISO standards

- Detailed analysis of failure modes through SEM or optical imaging

- Expertise covering metals, polymers, biomaterials, and medical devices

- Clear reporting that supports process optimization and quality assurance

We help you understand how surface quality impacts performance, durability, and reliability.