Light Interferometry & Optical Profilometry

Light interferometry and optical profilometry are non-contact surface metrology techniques that use reflected light to measure surface height, texture, and topography with sub-micron vertical resolution. By avoiding physical contact, these methods are ideally suited for delicate, soft, polished, or highly sensitive surfaces where traditional stylus-based techniques may cause damage or distortion.

At Materials Metric, optical profilometry and interferometric analysis are used to quantify surface roughness, step height, feature depth, waviness, and planar uniformity, as well as to identify micro-defects, wear patterns, and coating thickness or uniformity. These techniques provide precise surface characterization supporting materials development, quality control, failure analysis, and performance evaluation across polymers, coatings, optics, electronics, and advanced materials.

Use of Optical Profilometry

Optical Profilometry is used to:

• Quantify nanoscale and microscale roughness

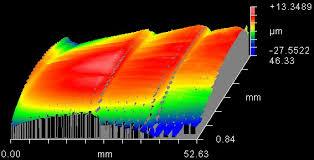

• Measure 2D and 3D surface topography

• Evaluate coatings, films, and thin layers

• Detect defects, scratches, or wear

• Analyze replication accuracy in molded or imprinted materials

• Verify surface preparation before bonding or coating

Applications of Optical Profilometry

- Polymers & Plastics: friction, adhesion, roughness

- Coatings & Thin Films: uniformity, thickness, micro-defects

- Metals: polishing quality, machining marks

- Biomaterials: scaffold surface architecture

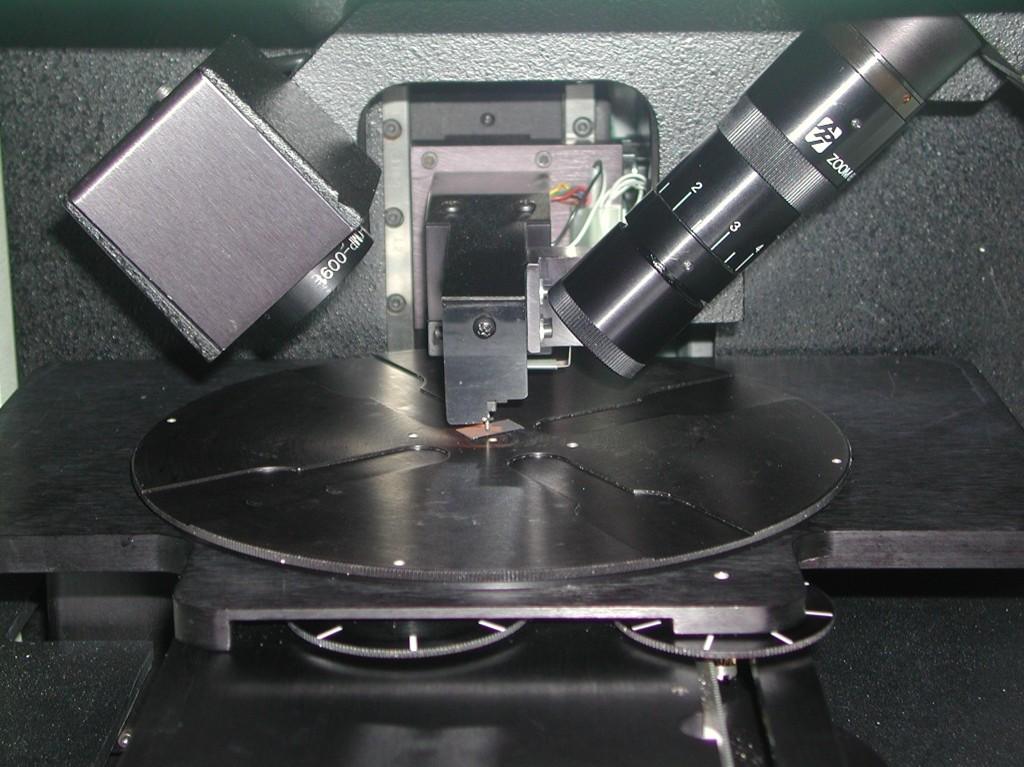

- Electronics: wafer topography, microfabrication features

- Medical Devices: surface finish and performance evaluation

Sample Analysis Process

1. Submission & Objective Review

- Specify area of interest and resolution requirements

- Provide material type to optimize reflectivity settings

2. Sample Preparation (Correct Procedure)

- Samples tested as-is; no dissolution

- Only light cleaning required to remove dust or surface particles

- Highly reflective materials may require anti-reflective coating

- Soft materials handled carefully to prevent deformation

3. Profilometry Measurement

- Non-contact scanning using white-light or interferometric methods

- 2D line scans or full 3D maps generated

- Optional high-magnification and zoomed-in regions

4. Data Processing & Reporting

- Roughness (Ra, Rq, Rz)

- Step height and feature depth

- 3D topography maps

- Defect detection and quantification

- Interpretation aligned with material performance

Why Choose Materials Metric for Your Optical Profilometry

Materials Metric offers high-precision, non-contact surface analysis ideal for delicate, complex, or engineered materials.

Our services include:

- Sub-micron vertical resolution for high-accuracy roughness quantification

- True 3D mapping for coatings, films, microstructures, and biomaterials

- Expertise linking topography to adhesion, wear, friction, and performance

- Non-destructive evaluation suitable for sensitive materials and medical devices

- Clear, quantitative reporting with actionable recommendations

We help you understand how surface morphology influences functional performance.