Differential Scanning Calorimetry (DSC)

What is Differential Scanning Calorimetry (DSC)?

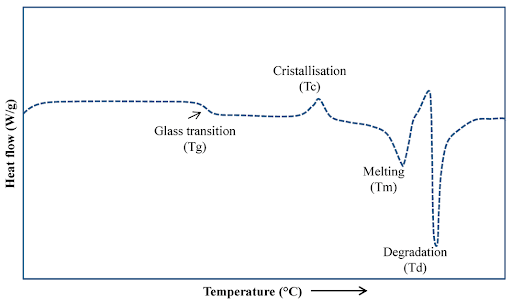

Differential Scanning Calorimetry (DSC) is a thermal analysis technique that measures heat flow into or out of a material as it is heated, cooled, or held under isothermal conditions. By tracking thermal transitions, DSC provides direct insight into phase changes and energy-related behavior that govern material performance.

At Materials Metric, DSC is used to determine glass transition temperature (Tg), melting and crystallization behavior, degree of crystallinity, thermal stability, and curing or crosslinking reactions. These measurements are essential for understanding how materials respond during processing, storage, and end-use, supporting polymers, pharmaceuticals, biomaterials, composites, and advanced material systems.

Use of DSC

DSC helps researchers:

• Determine Tg, melting point (Tm), crystallization temperature (Tc)

• Quantify polymer crystallinity

• Analyze curing kinetics and crosslinking behavior

• Assess thermal stability and formulation changes

• Compare thermal profiles before/after aging, sterilization, or processing

• Verify polymer blends, additives, and composite structures

Applications of DSC

- Polymers & Plastics: crystallinity, Tg, blend compatibility

- Biomaterials: hydrogel transitions, degradation profiles

- Pharmaceuticals: polymorphs, purity, API melting

- Composites: resin behavior and crosslink density

- Coatings & Adhesives: curing profiles and thermal reactivity

Sample Analysis Process

1. Submission & Objective Review

- Provide sample type, expected transitions, and testing goals

- Define heating/cooling rates and temperature range

2. Sample Preparation (Correct Procedure)

- Samples are tested as solids—no dissolution required

- Powders, pellets, films, fibers, and small sections are placed into aluminum pans

- Hermetic pans used for volatile, hydrated, or oxygen-sensitive materials

- No solvents or liquid preparation is used

- Sample masses are accurately recorded for enthalpy calculations

3. DSC Testing

- Controlled heating/cooling cycles

- Heat flow recorded vs. temperature

- Optional modulated DSC (mDSC) for resolving overlapping events

4. Data Processing & Reporting

• Tg, Tm, Tc, crystallinity %, ΔH

• Annotated thermograms

• Interpretation aligned with material behavior, formulation, and processing history

Why Choose Materials Metric for Your DSC Analysis

Materials Metric delivers high-accuracy thermal transition analysis with scientific precision. Our DSC services offer:

- Highly repeatable Tg, Tm, Tc, and crystallinity measurements

- mDSC capabilities for complex thermal profiles

- Deep expertise across polymers, biomaterials, adhesives, and pharmaceuticals

- Comparative thermal analysis before/after processing, aging, sterilization, or formulation changes

- Regulatory-ready reporting supporting ISO 10993, FDA submissions, and materials qualification

You receive actionable thermal insights, not just raw curves.