The development of biomaterials has always relied on deep scientific understanding, careful experimentation, and long validation cycles. Today, artificial intelligence is reshaping this landscape. By integrating machine learning with materials science, researchers and companies are accelerating discovery, improving predictive accuracy, and reducing cost and time in bringing next-generation biomaterials to market.

At Materials Metric, we see AI not as a replacement for scientific expertise, but as a powerful extension of it. Below are the core ways AI is already transforming biomaterials research and why this shift represents the future of the field.

Faster Discovery Through Data-Driven Material Design

Traditional biomaterials research often requires testing hundreds of formulations to identify one promising candidate. AI models can rapidly narrow this search space by learning from existing datasets and predicting which compositions will likely meet performance, safety, or biocompatibility targets.

Solid advantages include:

Predicting mechanical, chemical, and biological behaviors before physical testing

Optimizing polymer blends, scaffolds, and coatings with fewer iterations

Identifying structure–property relationships hidden from manual analysis

This accelerates initial discovery and allows scientists to begin experiments with a much more refined set of candidates.

Improving Biocompatibility and Safety Predictions

Understanding how a material interacts with cells and tissues is essential in medical device and regenerative medicine applications. AI enhances this process by recognizing patterns across large biological datasets.

Applications include:

Predicting cytotoxicity, inflammatory response, and degradation behavior

Modeling long-term biostability without years of physical aging studies

Screening surface chemistries for optimal protein adsorption or cell adhesion

This reduces risk early in development and strengthens preclinical decision-making.

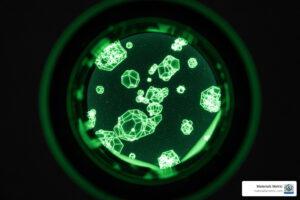

AI-Enhanced Microscopy and Imaging

Advanced imaging tools such as SEM, TEM, AFM, CLSM, and X-ray based techniques generate extraordinary detail, but also enormous data volumes. AI brings clarity and speed to this complexity.

Examples:

Automated defect detection in scaffolds, hydrogels, and polymer networks

Image segmentation to quantify porosity, fiber alignment, or surface roughness

Enhanced contrast and noise reduction for low-signal biological samples

These capabilities allow Materials Metric scientists to extract more meaningful insights from every dataset.

Accelerating Additive Manufacturing and Scaffold Optimization

AI supports the design of custom 3D-printed biomaterial scaffolds by:

Optimizing pore geometry for nutrient transport and mechanical strength

Predicting printability based on rheological properties

Simulating layer-by-layer behavior to eliminate print failures

With AI, additive manufacturing moves from trial-and-error to precision engineering.

Personalized and Patient-Specific Material Solutions

In the future, biomaterials will increasingly be tailored to individual patient needs. AI enables this by integrating clinical, imaging, and biomaterial datasets.

Possibilities include:

Customized implants based on patient anatomy and load requirements

Tailored degradation rates for tissue-specific regeneration

AI-guided selection of surface modifications for improved integration

This trend aligns with the broader shift toward precision medicine.

Reducing Development Costs and Time to Market

By predicting outcomes, minimizing failed experiments, and supporting regulatory documentation, AI shortens the path from concept to commercialization. Companies adopting AI-enhanced materials development will benefit from:

Fewer experimental cycles

Stronger evidence packages for FDA and ISO submissions

Earlier risk detection and mitigation

AI delivers efficiency without compromising scientific rigor.

Why AI Represents the Future of Biomaterials

Biomaterials sit at the intersection of biology, chemistry, engineering, and computational science. The increasing complexity of modern devices and therapeutic platforms demands analytical horsepower that extends beyond traditional methods. AI offers exactly that scalable, predictive, pattern-driven insight.

The future will be defined by:

Smart biomaterials that adapt to their environment

AI-designed scaffolds and implants with programmed behaviors

Fully digital R&D pipelines that integrate modeling, testing, and validation

As this transformation continues, organizations prepared with advanced analytics, robust experimental capabilities, and cross-disciplinary expertise will lead the next wave of materials innovation.

How Materials Metric Supports AI-Enabled Biomaterials Development

Materials Metric combines advanced analytical testing, microscopy, spectroscopy, mechanical evaluation, and data science to support organizations developing the next generation of biomaterials. Our scientists work across polymers, ceramics, composites, hydrogels, and tissue-engineering constructs, providing both experimental data and AI-assisted interpretation.

Whether you are optimizing a scaffold, characterizing a new polymer, validating biocompatibility, or integrating AI into your R&D workflow, our team is ready to support you.

Contact Materials Metric

Phone: 804-404-6414

Website: https://materialsmetric.com/

Email: info@materialsmetric.com

Follow us on LinkedIn for more insights and case studies.