X-ray Photoelectron Spectroscopy (XPS)

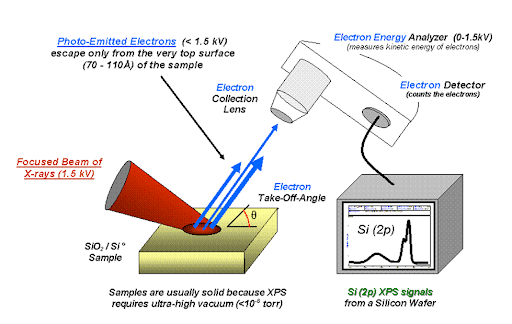

X-ray Photoelectron Spectroscopy (XPS) is a surface-sensitive analytical technique that measures the kinetic energy of electrons emitted from a material when irradiated with X-rays. Because the detected electrons originate from the top 5–10 nm of the surface, XPS provides highly accurate insight into surface chemistry and interfacial composition.

At Materials Metric, XPS is used to determine elemental composition, oxidation states, and chemical bonding environments, as well as to evaluate surface contamination, coatings, and thin films. This capability is essential for understanding how surface chemistry influences adhesion, corrosion resistance, biocompatibility, catalytic activity, and coating performance across polymers, metals, ceramics, and advanced materials.

Use of XPS

XPS is used to:

• Identify elements present on a surface

• Determine oxidation states (e.g., Fe²⁺/Fe³⁺, Ti⁴⁺, etc.)

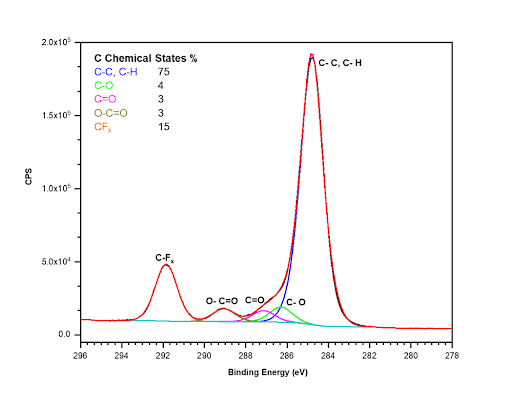

• Analyze chemical bonding and functional groups

• Evaluate plasma treatments, coatings, or surface modifications

• Detect contamination or thin-film defects

• Characterize corrosion layers and oxides

Applications of XPS

• Polymers: plasma treatment verification, surface activation

• Metals/Alloys: corrosion, oxide layer composition

• Medical Devices: implant surface chemistry

• Coatings/Thin Films: uniformity, chemical stability

• Electronics: semiconductor and interface analysis

• Catalysts: oxidation states and binding environments

Sample Analysis Process

1. Submission & Review

- Define elements/chemistries of interest

• Provide surface history (cleaning, coating, exposure)

2. Sample Preparation

- Mounting on tabs

• No coating required

• Optional sputter cleaning (if appropriate)

3. XPS Measurement

- Survey scans for elemental composition

• High-resolution (HR-XPS) scans for chemical states

• Depth profiling (if requested)

4. Data Processing & Reporting

- Peak fitting and chemical state interpretation

• Atomic percent composition

• Clear discussion of surface chemistry results

Why Choose Materials Metric for Your XPS Analysis

Materials Metric provides precise XPS analysis with expert interpretation. Our services include:

- Chemical state identification for metals, polymers, and coatings

• Surface contamination detection

• Oxide layer and corrosion evaluation

• Quantitative elemental and chemical composition

• HR-XPS for detailed bonding information

• Clear reports optimized for R&D and regulatory use

By pairing XPS with XRD, SEM, and ICP, we provide a complete understanding of both surface chemistry and bulk structure.