Micro & Nano Mechanical Testing (Nanoindentation)

Micro and nano mechanical testing evaluates how materials respond to precisely controlled mechanical loads applied at micron- and nanometer-scale depths. By probing localized regions, these techniques reveal mechanical properties that cannot be resolved through bulk testing, particularly where surface or subsurface behavior governs performance.

At Materials Metric, micro- and nano-scale mechanical testing, including nanoindentation is used to quantify hardness, elastic modulus, creep behavior, time-dependent deformation, plasticity, recovery, and local mechanical anisotropy. This testing is essential for thin films, surface coatings, microstructures, biological substrates, and small-volume material systems where localized mechanical integrity is critical to functionality and reliability.

Use of Nanoindentation & Micro-Mechanical Testing

This testing is used to:

• Characterize small-scale mechanical properties

• Evaluate thin-film hardness and modulus

• Assess coating durability and mechanical integrity

• Measure creep, viscoelasticity, and time-dependent response

• Compare mechanical behavior across microstructural regions

• Evaluate biomaterials, hydrogels, and engineered tissues

Applications

- Coatings & Thin Films: hardness, modulus, wear performance

- Biomaterials: hydrogel stiffness, tissue substrate mechanics

- Metals & Ceramics: grain-level mechanical properties

- Polymers: viscoelastic indentation response

- Composites: fiber/matrix micro-mechanics

- Microelectronics: film stack characterization

Sample Analysis Process

1. Submission & Objective Review

- Define indentation depth, load range, and mapping needs

- Provide film thickness or substrate information if applicable

2. Sample Preparation

- Surfaces polished or leveled to ensure smooth indentation

- Thin films mounted for stable support

- Soft or hydrated materials stabilized in controlled environments

3. Mechanical Testing

- Indentation performed at controlled loading rates

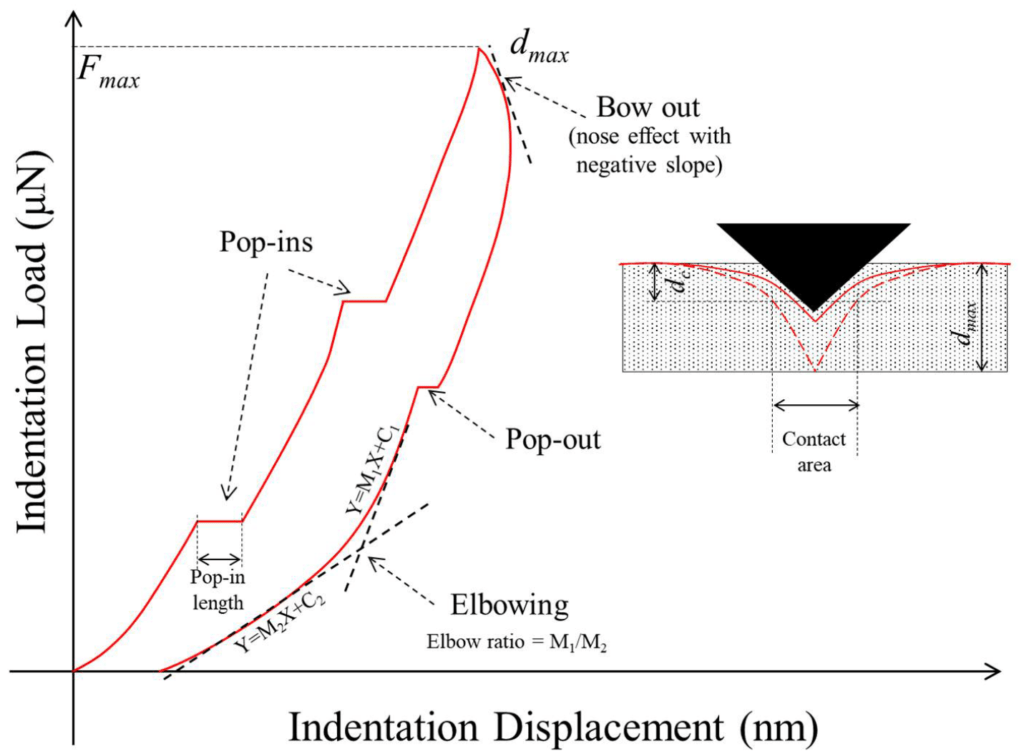

- Load–displacement curves recorded

- Creep or hold segments added when needed

- Grid or array indentation available for mapping

4. Data Processing & Reporting

- Hardness (H) and modulus (E)

- Creep rate and time-dependent deformation

- Residual depth and recovery

- Load–displacement curves

- Interpretation connecting results to durability and structure

Why Choose Materials Metric for Micro/Nano Mechanical Testing

Materials Metric provides precision micro- and nano-scale mechanical characterization for advanced materials and surfaces.

Our services offer:

- High-resolution measurement of modulus, hardness, and creep

- Capability for spatial mapping across films and microstructures

- Expertise in polymers, biomaterials, thin films, ceramics, and composites

- Integration with surface imaging (SEM, profilometry) for failure interpretation

- Clear reporting with engineering analysis for R&D, quality control, and product qualification

We help you understand the mechanical behavior of materials where traditional testing cannot reach.