Laser Diffraction Particle Size Analysis

Laser Diffraction Particle Size Analysis is a robust and widely adopted technique for determining particle size distribution by measuring the angular scattering of laser light as it passes through a dispersed material. The method supports an exceptionally broad size range from submicron particles to millimeter-scale granules and accommodates both dry powder dispersion in air and wet dispersion in liquid media.

At Materials Metric, laser diffraction is used to deliver rapid, reproducible, and statistically reliable particle size data for powders, slurries, emulsions, suspensions, granulated materials, and multiphase systems. This versatility makes it an essential tool for formulation development, process optimization, dispersion stability assessment, flow behavior analysis, and batch-to-batch quality control across pharmaceutical, biomaterial, energy, chemical, and advanced materials applications.

Use of Laser Diffraction

Laser diffraction is used to:

• Measure complete particle size distribution (D10, D50, D90)

• Compare batch-to-batch variation in powders

• Optimize milling, grinding, granulation, and spray-drying processes

• Evaluate dispersion quality and detect agglomeration

• Characterize suspensions, emulsions, and dispersible powders

• Ensure consistency in formulated products

Applications

- Polymers, plastics, and elastomers

- Pharmaceuticals and drug delivery powders

- Ceramics, minerals, and catalysts

- Biomedical scaffolds and bioactive powders

- Food ingredients and agricultural materials

- Additive manufacturing powders

- Battery and energy materials (cathode/anode powders)

Sample Analysis Process

1. Submission & Objective Review

- Identify material state (dry, slurry, suspension, granule)

- Provide refractive index if known (optional but beneficial)

- Define expected size range and performance requirements

2. Sample Preparation

- Dry dispersion:

– Powders dispersed through controlled air pressure or mechanical agitation - Liquid dispersion:

– Sample dispersed in a selected liquid medium

– Mild sonication used to break agglomerates when appropriate

– Dispersants applied only when needed to ensure stability - Sample handling tailored to prevent alteration of fragile particles

3. Laser Diffraction Measurement

- Laser beam passes through the dispersed particles

- Scattering pattern captured across multiple detectors

- Advanced models applied to calculate size distribution

- Real-time data monitoring ensures dispersion quality

4. Data Processing & Reporting

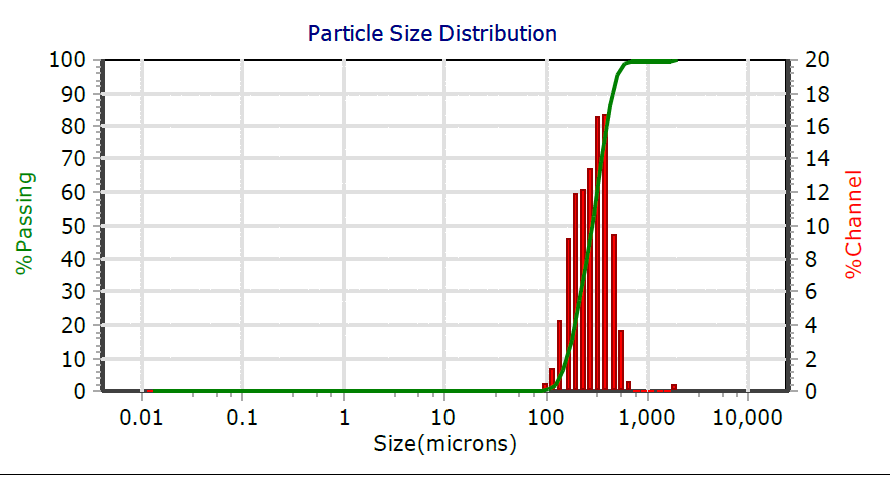

- Full particle size distribution (volume, number, or intensity)

- D10, D50, D90 and span calculations

- Graphical distribution plots

- Comparison of multiple batches if needed

- Interpretation linked to processing, formulation, or performance goals

Why Choose Materials Metric

Materials Metric provides accurate and reproducible particle size analysis across a broad size range using state-of-the-art laser diffraction systems.

Our advantages include:

- Flexible dry and wet dispersion for accurate analysis of powders or liquids

- Expertise with fragile, cohesive, or highly polydisperse materials

- Tailored sample preparation that preserves particle integrity

- Support for formulation development and manufacturing control

- Clear, publication-ready reporting with statistical interpretation

We help ensure precise particle sizing that supports R&D, quality assurance, and process optimization.