Integration with Experimental Testing

Integration with Experimental Testing bridges computational modeling with real laboratory data to create a unified, accurate, and highly predictive understanding of material and biological performance. By combining simulations (mechanical, thermal, molecular, genomic, statistical, or AI-driven) with empirical results from microscopy, spectroscopy, mechanical testing, chemical analysis, or biological assays, this approach ensures that models reflect real-world conditions and experiments are designed more efficiently.

This integrated framework strengthens decision-making, reduces experimental burden, accelerates development timelines, and provides high-confidence insights suitable for research, product development, and regulatory submissions.

Materials Metric brings together computational analytics and ISO 9001:2015, aligned laboratory testing to deliver a complete, validated scientific picture.

Integration Enhances Research & Development

1. Model Validation & Refinement

Validate computational models using real experimental measurements

Adjust parameters to improve accuracy and reduce uncertainty

Strengthen predictive power for materials, devices, and biological systems

2. Experiment Design Guided by Simulation

Use modeling to identify the optimal test conditions

Reduce unnecessary experiments and increase efficiency

Prioritize high-impact tests based on predictive outputs

3. Multi-Modal Data Fusion

Combine imaging (SEM/TEM/CLSM), spectroscopy (FTIR, Raman, NMR), mechanical curves, thermal data, and biological assays

Build an integrated dataset for deeper interpretation

Create correlations between structure, composition, and performance

4. Mechanistic Insight & Hypothesis Development

Reveal underlying causes of failure, degradation, or biological response

Predict long-term behavior and validate mechanisms experimentally

Enable targeted material modifications supported by evidence

5. Streamlined Regulatory & Technical Documentation

Use combined computational + experimental datasets for submission packages

Provide quantitative evidence for device performance, safety, and risk mitigation

Support GLP/ISO-aligned reporting for preclinical and material validation

Applications We Support

Materials Science & Engineering

Validating stress–strain predictions with mechanical testing

Confirming molecular modeling results with spectroscopy or thermal data

Linking microstructure (SEM/TEM) to mechanical or thermal behavior

Medical Devices & Biomaterials

Pairing simulation-based wear/fatigue predictions with bench studies

Validating cell adhesion, protein adsorption, and tissue-interface models

Correlating surface modeling results with in-vitro performance

Pharmaceutical & Formulation Science

Using dissolution or stability simulations to design focused experiments

Confirming impurity or degradation predictions with chromatographic testing

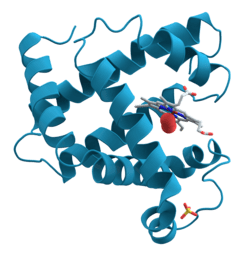

Linking molecular docking outputs to in-vitro activity

Antimicrobial & Biofilm Analysis

Predicting antimicrobial resistance trends and validating them in vitro

Using AI-based biofilm models to guide CLSM/SEM imaging and quantification

Computational Biology & Toxicology

Testing QSP or PK/PD predictions with experimental bioassays

Confirming genomic or molecular docking predictions with wet-lab data

Integration Workflow at Materials Metric

1. Pre-Study Assessment

Define computational models and experimental objectives

Identify datasets required for validation or hypothesis testing

2. Computational Simulation

Run mechanical, thermal, chemical, molecular, or AI-driven models

Predict outcomes, highlight variables, and narrow the testing focus

3. Experimental Execution

Perform microscopy, spectroscopy, mechanical testing, thermal analysis, or biological assays

Generate high-quality empirical data

Follow ISO 9001:2015–aligned procedures throughout

4. Data Fusion & Comparative Analysis

Compare empirical results with simulation predictions

Apply statistical and quantitative metrics to evaluate agreement

Identify discrepancies and adjust models as needed

5. Reporting & Translational Insights

Provide unified computational + experimental reports

Deliver design recommendations and next-step strategies

Prepare optional regulatory-supporting documentation

Why Choose Materials Metric

Materials Metric is uniquely positioned as both a computational modeling provider and a multi-disciplinary analytical testing CRO, allowing us to seamlessly connect simulations with laboratory data.

We offer:

ISO 9001:2015–certified quality systems ensuring scientific rigor

Access to advanced experimental platforms (SEM/TEM/AFM, FTIR, NMR, HPLC/GC-MS, DSC/TGA, mechanical testing, biofilm imaging, biocompatibility assays)

State-of-the-art computational tools (FEM, molecular modeling, AI/ML, QSP, PK/PD)

Cross-disciplinary expertise spanning materials science, biomedical engineering, analytical chemistry, microbiology, and pharmacometrics

Regulatory-ready documentation for medical device, pharmaceutical, and materials submissions

Collaborative, end-to-end R&D support from model creation to experimental interpretation

This integrated approach enables faster development, higher accuracy, reduced costs, and greater confidence in scientific and engineering decisions