Integrated Chemical + Microscopy Characterization

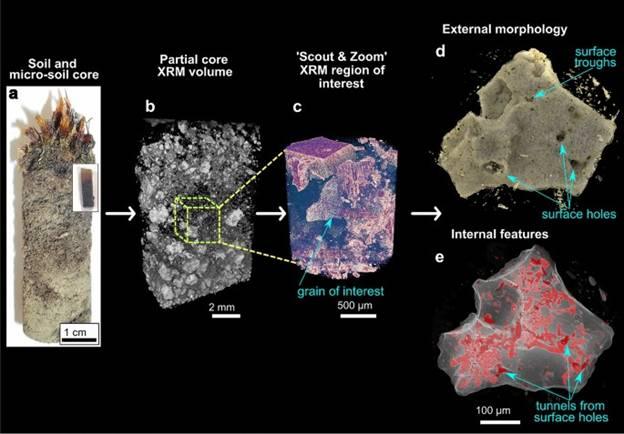

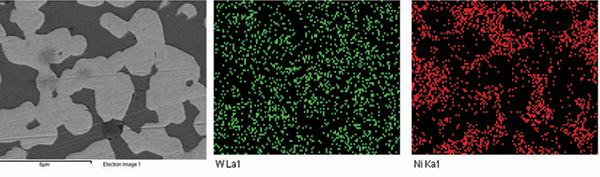

Integrated chemical and microscopy characterization combines high-resolution imaging with advanced chemical analysis to correlate structure, composition, and performance within a unified analytical framework. By linking microstructural features with chemical signatures, this approach delivers a holistic understanding of material behavior that cannot be achieved through a single technique alone.

At Materials Metric, integrated workflows merge SEM, TEM, AFM, and confocal microscopy with complementary chemical tools such as EDS, XPS, FTIR, Raman spectroscopy, ICP, and chromatography. This multi-modal strategy reveals how microstructure, defects, elemental distribution, and chemical bonding collectively influence material performance, durability, and reliability, supporting R&D, failure investigation, and regulatory submissions.

Uses of Integrated Characterization

• Link chemical composition with microstructure

• Identify defect chemistry, crack propagation, and failure origins

• Characterize coatings, interfaces, and diffusion layers

• Evaluate filler dispersion, polymer phase separation, or nanoparticle distribution

• Combine optical, electron, and chemical signatures for full material profiling

• Support R&D, troubleshooting, and regulatory documentation

Applications

• Biomaterials & implant surfaces

• Medical device coatings & drug-eluting systems

• Polymers, composites, elastomers

• Ceramics, metals, and specialty alloys

• Battery, catalyst, and semiconductor materials

• Printed/3D materials and advanced manufacturing

Sample Analysis Process

1. Study Design

- Define structural and chemical objectives

- Select appropriate microscopy + chemical techniques

2. Sample Preparation

- Cross-sectioning, embedding, or polishing

- Conductive or non-conductive preparation

- Hydrated or biological preparation (when needed)

3. Multi-Modal Characterization

- SEM/TEM/AFM imaging for topology and microstructure

- EDS/XPS/XRF for chemical composition and surface bonding

- FTIR/Raman for molecular information

- ICP/HPLC/GC–MS for bulk chemical confirmation

- Integrated datasets for correlation

4. Reporting

- Correlated chemical–microstructural interpretation

- High-resolution images with annotated chemical findings

- Failure, interface, or defect analysis

- Recommendations for process optimization or reformulation

Why Choose Materials Metric for Integrated Characterization

Materials Metric delivers comprehensive, multi-dimensional material understanding by combining imaging, chemistry, and structure into one cohesive analysis.

We provide:

• Multi-Technique Expertise Under One Workflow

SEM, TEM, AFM, EDS, XPS, Raman, FTIR, ICP, HPLC, and more—integrated into a single, coherent dataset.

• Root-Cause & Interface-Focused Analysis

We specialize in identifying chemical and structural drivers behind failure, diffusion, coating issues, and performance degradation.

• Skilled Interpretation Across Material Systems

Polymers, biomaterials, metals, ceramics, composites, coatings, nano-materials—each requires specific expertise. We bring that depth.

• Regulator-Ready Reports

Well-structured, highly visual, clearly interpreted datasets for FDA, ISO, and internal QA frameworks.

• Insights That Directly Support R&D & Manufacturing

We don’t just provide data—we explain what it means and how to improve your material or process.

Materials Metric enables you to see the chemistry behind the structure, providing unmatched clarity for product development, troubleshooting, and innovation.

Related services