Dynamic Mechanical Analysis (DMA)

Dynamic Mechanical Analysis (DMA) characterizes the viscoelastic behavior of materials by applying small oscillatory forces while precisely controlling temperature, frequency, or time. By measuring the material’s response to dynamic loading, DMA provides detailed insight into mechanical performance across thermal and operational conditions.

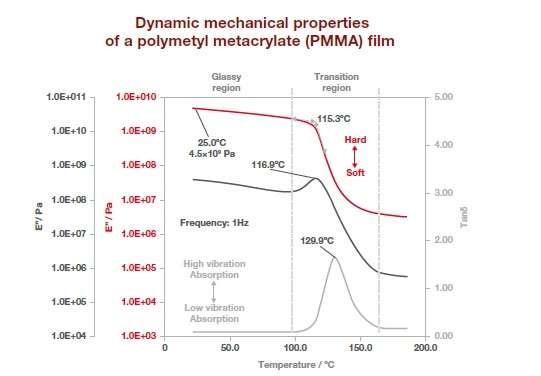

At Materials Metric, DMA is used to determine storage modulus (E′) representing elastic behavior, loss modulus (E″) representing viscous behavior, damping factor (tan δ), glass transition temperature (Tg), and relaxation or creep behavior. DMA is one of the most sensitive techniques for assessing mechanical integrity, phase transitions, and performance stability in polymers, composites, biomaterials, and advanced engineering materials

Use of DMA

DMA is used to:

• Determine temperature-dependent stiffness and damping

• Measure Tg more sensitively than DSC

• Assess curing and crosslinking of polymers and adhesives

• Characterize time-, temperature-, or frequency-dependent behavior

• Predict performance under real-world dynamic loading

• Understand viscoelastic transitions in biomaterials and composites

Applications of DMA

- Polymers & Composites: modulus, damping, Tg behavior

- Adhesives & Coatings: curing, crosslinking, viscoelasticity

- Biomaterials: mechanical behavior in hydrated environments

- Medical Devices: fatigue, flexibility, and durability under thermal load

- Packaging: stiffness and deformation under dynamic stress

Sample Analysis Process

1. Submission & Objective Review

- Select test mode: tension, dual cantilever, bending, shear, or compression

- Define test type: temperature sweep, frequency sweep, time sweep

2. Sample Preparation

- Samples are tested in solid form, not dissolved

- Cut to precise dimensions according to instrument geometry

- Films, bars, or molded parts must meet strict dimensional tolerances

- Hydrated materials may be tested in controlled humidity or submerged environment

- No solvents are used for preparation

3. DMA Testing

- Oscillatory loading applied during controlled temperature ramp

- Frequency or time-domain testing performed as required

- Real-time modulus and damping recorded

4. Data Processing & Reporting

- E’, E’’, tan δ curves

- Tg determination

- Modulus transitions and relaxation events

- Interpretation tied to mechanical performance, durability, and stability

Why Choose Materials Metric for Your DMA Analysis

Materials Metric provides advanced viscoelastic testing backed by deep expertise in materials science and biomedical engineering.

Our DMA services include:

- Highly sensitive Tg and transition detection

- Full viscoelastic profiling across temperature and frequency

- Multi-mode testing for films, solids, hydrogels, foams, and composites

- Curing and crosslink studies for adhesives and coatings

- Clear, engineering-focused interpretation connecting data to performance, fatigue behavior, and product design

We provide DMA results that support R&D, quality control, regulatory submissions, and mechanical reliability decisions.