Degradation & Impurity Tracking

Degradation and impurity tracking evaluates how materials and formulations chemically evolve over time by identifying breakdown products, oxidation and hydrolysis pathways, additive depletion, monomer release, and the formation of new impurities. These chemical changes can significantly impact shelf life, safety, mechanical performance, and regulatory acceptability, particularly under real-time or accelerated aging conditions, environmental exposure, or sterilization stress.

At Materials Metric, degradation and impurity tracking integrates chromatographic, spectroscopic, mass spectrometric, thermal, and elemental techniques to build a comprehensive understanding of material aging and lifecycle behavior. Our data-driven approach supports stability studies, root-cause failure investigations, formulation optimization, and robust regulatory documentation for complex materials and finished products.

Uses of Degradation & Impurity Tracking

This testing is used to:

- Detect early-stage degradation products

- Track impurity growth under thermal, oxidative, or humidity stress

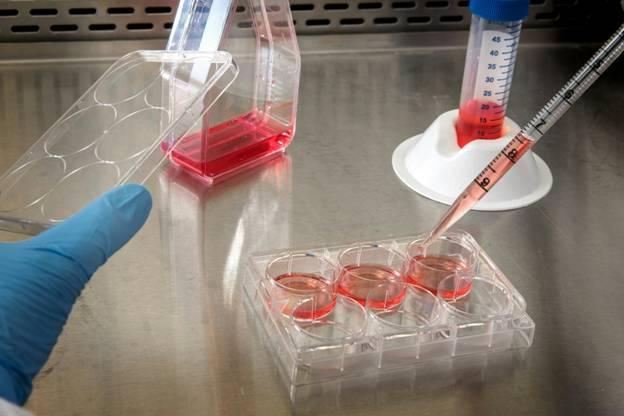

- Evaluate material compatibility with drugs, biological fluids, or chemicals

- Confirm long-term formulation and packaging stability

- Support shelf-life determination and accelerated aging studies

- Investigate material failures or unexpected behavior

- Build regulatory-ready impurity profiles for submissions

Applications

Degradation and impurity tracking is critical for:

- Polymers, elastomers & biomaterials

- Pharmaceuticals & intermediates

- Medical devices & implantables

- Coatings, adhesives, inks & sealants

- Battery materials, composites & resins

- Consumer products, packaging systems

- Industrial chemicals and specialty materials

Sample Analysis Process

1. Study Definition

- Identify aging conditions (thermal, humidity, oxidative, UV)

- Establish analytical endpoints and regulatory needs

2. Accelerated or Real-Time Aging

- Controlled exposure using defined environmental conditions

- Time-point sampling for degradation progression

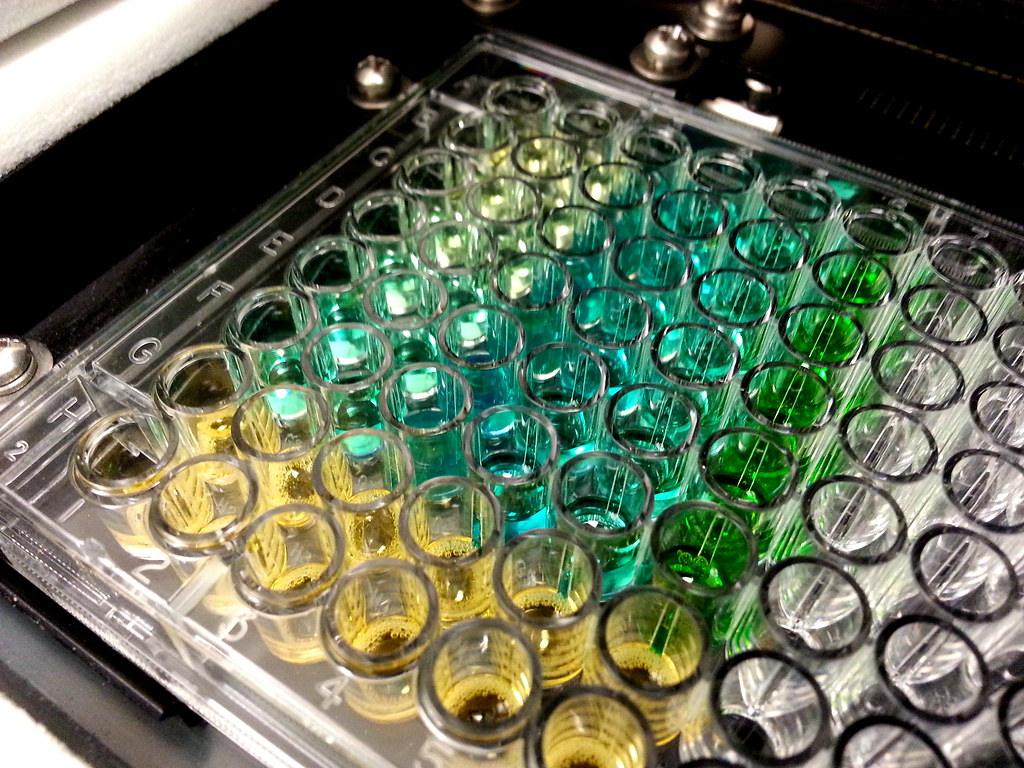

3. Analytical Characterization

We use a multi-dimensional analytical approach:

- HPLC / UPLC for non-volatile impurities & degradants

- GC–MS for volatile degradation by-products

- LC–MS for structural elucidation

- ICP–MS/ICP–OES for elemental changes

- FTIR / Raman for chemical structure shifts

- DSC / TGA for thermal degradation behavior

4. Reporting

- Identification & quantification of impurities

- Degradation pathway mapping

- Time-dependent degradation profiles

- Stability interpretation & shelf-life considerations

- Recommendations for formulation or material improvements

Why Choose Materials Metric for Degradation & Impurity Tracking

Materials Metric provides scientifically rigorous degradation analysis with a level of chemical insight essential for high-risk and regulated applications.

• Comprehensive Degradation Chemistry Expertise

We understand oxidative, hydrolytic, thermal, biological, and photolytic degradation mechanisms—and how they influence product safety and performance.

• Integrated Multi-Technique Testing

Our approach combines chromatography, MS, spectroscopy, and thermal analysis to deliver complete chemical clarity.

• Predictive Chemical Insight

We map degradation pathways and interpret what each impurity means for stability and regulatory compliance.

• Support for ISO, ICH, and FDA Requirements

Our data structures follow regulatory expectations for pharmaceuticals, biomaterials, medical devices, and consumer products.

• Actionable Recommendations for Product Improvement

We provide direction for material selection, formulation optimization, packaging compatibility, and long-term stability enhancement.

Materials Metric delivers high-confidence impurity profiles that help safeguard quality, ensure compliance, and strengthen product reliability.