Biofilm Formation & Resistance Studies

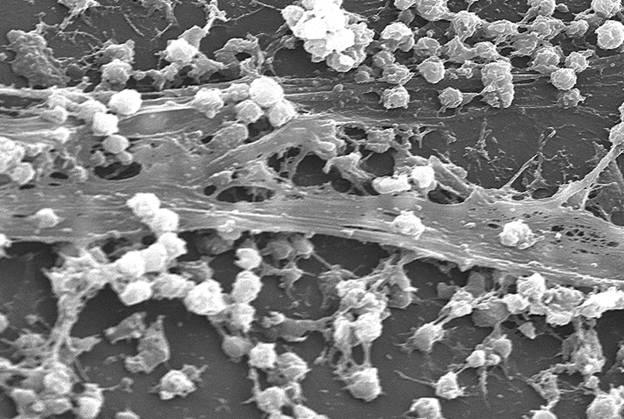

Biofilm Formation & Resistance Studies examine how microorganisms adhere to material surfaces, proliferate, and develop structured, highly resistant microbial communities under realistic conditions. Biofilms significantly increase tolerance to antibiotics, disinfectants, and environmental stress, making them a critical challenge for medical devices, implants, wound-care systems, water-contact materials, and antimicrobial coatings.

At Materials Metric, we design clinically and application-relevant biofilm models to evaluate surface susceptibility, antimicrobial durability, and resistance mechanisms. By integrating controlled biofilm growth assays, quantitative viability measurements, and structural characterization, we generate actionable insight into how materials perform against one of the most persistent biological threats in real-world use.

Methods & Models Used in Biofilm Testing

Materials Metric performs both standardized and custom-designed biofilm models tailored to your product’s clinical or functional use.

Common Biofilm Assay Types

Static biofilm models

Surface attachment & growth on coupons, films, implants, coatingsDynamic flow systems

Flow cells simulating real physiological or environmental flowCDC Biofilm Reactor®

Industry-standard system for reproducible biofilm formationMicrotiter plate assays

Crystal violet staining, metabolic assays, viability stainingConfocal microscopy-based 3D biofilm imaging

Structural analysis and viability mappingCustom microbial challenge models

For novel materials, wound dressings, or antimicrobial surfaces

Microorganisms commonly tested

Staphylococcus aureus

Staphylococcus epidermidis

Pseudomonas aeruginosa

E. coli

Candida albicans

Mixed-species biofilms

Applications of Biofilm Formation & Resistance Studies

Medical Devices & Implants

Catheters, orthopedic implants, dental materials, wound dressings, meshes, and stents.

Biomaterials & Coatings

Hydrogels, antimicrobial coatings, nanostructured surfaces, and bioactive films.

Water & Environmental Systems

Filters, membranes, piping components, HVAC surfaces, and disinfection technologies.

Pharmaceutical & Topical Formulations

Antibiofilm gels, ointments, sprays, and drug-eluting coatings.

Industrial & Consumer Products

Surface treatments, antimicrobial plastics, and packaging materials.

Sample Analysis Process

1. Study Design & Parameter Selection

Selection of microbial species

Determination of environmental or clinical conditions

Flow/static model selection

2. Surface Preparation & Conditioning

Sterilization, hydration, or coating preparation

Application of antimicrobial or protective treatments

3. Biofilm Growth & Challenge Exposure

Controlled incubation under static or dynamic conditions

Biofilm establishment over hours to weeks

4. Quantitative & Qualitative Analysis

CFU enumeration

Crystal violet staining

Biomass quantification

Viability staining (Live/Dead)

SEM and CLSM imaging for ultrastructure visualization

5. Resistance & Removal Evaluation

Exposure to antimicrobials or cleaning agents

Measurement of remaining viability and biofilm structure

Evaluation of detachment and regrowth behavior

6. Data Interpretation & Reporting

Full dataset with biofilm quantification

Imaging-based evidence

Performance comparison against controls

Recommendations for optimization

Why Choose Materials Metric

Materials Metric provides rigorous, realistic biofilm models that match clinical and industrial conditions.

We offer:

• Controlled flow-cell and static biofilm systems

• ISO 9001:2015 accredited processes

• Expertise in antimicrobial materials and biological interactions

• Integrated imaging (SEM, CLSM, AFM) for structural insights

• Mechanistic interpretation for product optimization

Materials Metric helps you understand how your materials perform against the toughest microbial challenges.

Related services