Atomic Absorption Spectroscopy (AAS)

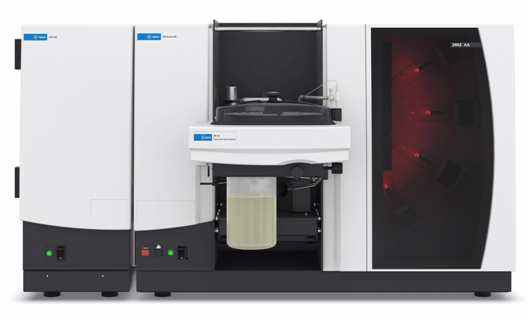

Atomic Absorption Spectroscopy (AAS) is a quantitative analytical technique used to measure specific metal elements within a sample with high sensitivity. In AAS, the sample is atomized, typically using a flame or graphite furnace and light at an element-specific wavelength is passed through the vaporized atoms. The amount of light absorbed is directly proportional to the concentration of the target metal.

At Materials Metric, AAS is applied for accurate elemental quantification across a wide range of metals, supporting contamination screening, materials characterization, quality control, and regulatory compliance testing. Our workflows deliver reliable, reproducible metal concentration data for polymers, biomaterials, pharmaceuticals, environmental samples, and advanced materials.

Use of Atomic Absorption Spectroscopy

AAS is used to measure metal concentrations in solid, liquid, or digested samples.

It allows researchers and manufacturers to:

• Quantify metal ions, trace metals, and heavy metals

• Verify alloy composition and elemental purity

• Detect catalyst residues in polymers and chemicals

• Assess metal leaching from biomaterials or medical devices

• Evaluate environmental and water samples for metal contamination

• Confirm elemental levels in ceramics, composites, and coatings

Applications of AAS

AAS supports a wide range of industries and testing scenarios:

• Biomaterials & Medical Devices: metal ion release, implant surface evaluation

• Polymers & Composites: catalyst residue, contamination profiling

• Environmental: water and soil metal analysis

• Metals & Ceramics: verification of alloy composition and raw material quality

• Food & Agriculture: trace metal verification for regulatory compliance

• Industrial Chemicals: purity and identification testing

Sample Analysis Process

1. Sample Submission & Objective Review

- Client provides sample type, expected metal species, and concentration range

- We determine whether flame AAS or graphite furnace AAS is appropriate

2. Sample Preparation

Preparation varies depending on material type:

• Acid digestion for polymers, biomaterials, and solids

• Dilution for aqueous samples

• Filtration to remove particulates

• Matrix modification (if needed) for interference control

3. AAS Measurement

- Flame AAS for moderate mg/L–µg/L concentrations

- Graphite furnace AAS for ultra-trace detection (ppb levels)

- Single-element lamp tuned to specific wavelengths

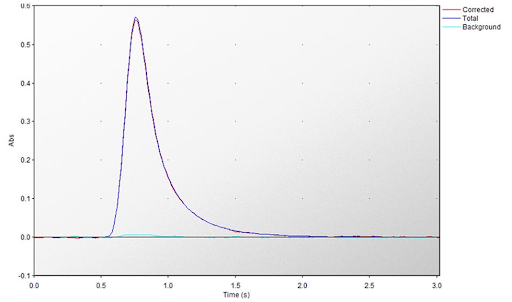

- Calibration with certified metal standards

4. Data Processing & Reporting

- Metal concentration values with units (ppm/ppb)

- Calibration curves and QA/QC verification

- Interpretation of compliance or specification limits

- Fully annotated final report summarizing key results

Why Choose Materials Metric for Your AAS Analysis

Materials Metric provides accurate, reliable, and scientifically validated AAS services for routine and trace metal quantification.

Our AAS capabilities offer:

- High-sensitivity metal detection using flame or graphite furnace techniques

• Robust accuracy through certified standards and validated digestion methods

• Capability to analyze diverse materials, including water, polymers, biomaterials, coatings, metals, ceramics, and environmental samples

• Customized digestion and preparation workflows for challenging matrices

• Clear, well-structured reports designed for R&D, manufacturing support, and regulatory submissions

By integrating AAS results with ICP–MS/OES, XRF, and chemical characterization, Materials Metric delivers a comprehensive understanding of metal content and contamination pathways.