Antimicrobial Efficacy Testing

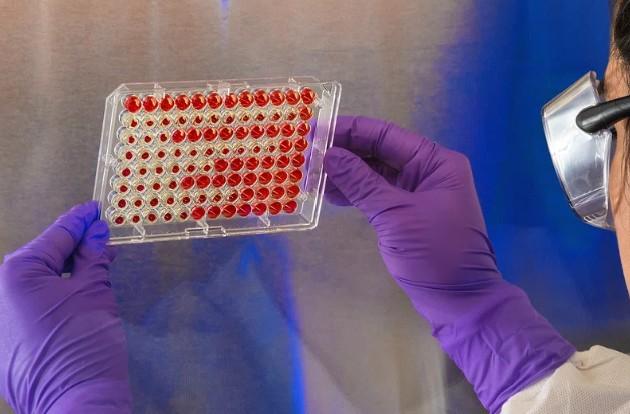

Accurately evaluating antimicrobial performance is critical for materials and products designed to resist microbial contamination, infection, or biofouling. Antimicrobial Efficacy Testing assesses whether materials, coatings, formulations, or devices can inhibit microbial growth, reduce viable pathogen levels, or prevent surface colonization under defined and reproducible conditions.

At Materials Metric, we apply standardized and custom antimicrobial assays, including log-reduction measurements, time-kill studies, zone-of-inhibition testing, and USP, ISO, and ASTM methods to generate quantitative, defensible performance data. These studies support product development, mechanism optimization, and regulatory submissions across medical devices, pharmaceuticals, wound-care systems, consumer products, and antimicrobial surface technologies.

Antimicrobial studies quantify:

Log reduction of viable microbes

Inhibition of growth zones or bacterial spreading

Bactericidal vs. bacteriostatic activity

Time-kill kinetics and rate of microbial reduction

Residual antimicrobial activity over time

Effectiveness under wet, dry, or physiological conditions

Common Test Standards & Methods

Materials Metric provides antimicrobial testing aligned with:

USP 51 (Antimicrobial preservative effectiveness)

ASTM E2315 (Time-kill studies)

ASTM E2149 (Dynamic contact antimicrobial test)

ISO 22196 / JIS Z 2801 (Antimicrobial surface activity)

ASTM E1428 (Challenge tests for biomaterials)

Custom microbial challenge models for novel materials and coatings

We test both Gram-positive and Gram-negative bacteria, fungi, and clinically relevant organisms.

Applications

Medical devices & implants

Catheters, wound dressings, sutures, orthopedic coatings, dental materialsBiomaterials & surface coatings

Antibacterial films, nanostructured surfaces, antimicrobial hydrogelsPharmaceuticals & topical formulations

Creams, gels, ointments, drug-loaded dressingsConsumer products & packaging

Antimicrobial plastics, textiles, personal care productsEnvironmental and industrial systems

Water treatment materials, HVAC coatings, filtration devices

Antimicrobial Efficacy Testing Process

1. Test Planning & Organism Selection

Identify target pathogens (e.g., S. aureus, E. coli, P. aeruginosa, C. albicans)

Define relevant standards, exposure conditions, and performance endpoints

2. Sample Preparation & Conditioning

Surface sterilization when required

Hydration, incubation, or environmental preconditioning

3. Microbial Challenge & Incubation

Apply microbes directly to sample surfaces

Expose samples under controlled temperature, humidity, and growth conditions

4. Quantification of Microbial Reduction

CFU enumeration

Log-reduction calculations

Viability staining for visual confirmation

Time-kill curves

5. Reporting & Interpretation

Full performance summary

Compliance with USP, ISO, ASTM guidelines

Recommendations to improve antimicrobial performance

Why Choose Materials Metric for Antimicrobial Efficacy Testing

Materials Metric provides highly controlled, reproducible antimicrobial testing backed by microbiology, materials science, and regulatory expertise.

We offer:

• ISO 9001:2015 accredited quality systems

• Validated antimicrobial assays including USP, ISO, and ASTM methods

• Quantitative log-reduction analysis with high sensitivity

• Expertise in coatings, hydrogels, polymers, and biomedical materials

• Integrated microscopy and biofilm analysis for deeper mechanistic insight

Materials Metric delivers accurate, regulator-ready antimicrobial performance data you can trust for R&D or submission packages.