Semiconductor materials testing is a critical foundation of the electronics and microelectronics industry. As devices become smaller, faster, and more complex, the performance and reliability of semiconductor materials must be validated with extreme precision. From wafer fabrication to advanced packaging, materials testing ensures that semiconductor devices meet stringent electrical, thermal, mechanical, and chemical requirements.

Materials Metric supports semiconductor innovation by delivering advanced materials testing, characterization, and data-driven insights tailored to the evolving needs of semiconductor manufacturers, startups, and R&D teams.

Why Materials Testing Is Essential for Semiconductor Devices

Semiconductor devices operate at the limits of material performance. Even minor defects or impurities can lead to device failure, yield loss, or long-term reliability issues. Materials testing provides the data needed to identify these risks early and guide design and process optimization.

Key reasons materials testing is essential in the semiconductor industry include:

Ensuring device reliability and long-term performance

Detecting defects, impurities, and microstructural inconsistencies

Supporting compliance with industry and customer specifications

Reducing costly manufacturing errors and yield loss

Enabling innovation in next-generation semiconductor technologies

Without rigorous testing, manufacturers risk performance degradation, shortened device lifetimes, and reputational damage.

Key Semiconductor Materials and Performance Considerations

Semiconductor performance is fundamentally determined by material selection. Each material offers unique electrical, thermal, and mechanical properties suited to specific applications.

Common semiconductor materials include:

Silicon (Si): The backbone of modern electronics due to its stability, availability, and well-understood properties

Gallium Arsenide (GaAs): Used in high-speed and optoelectronic applications

Silicon Carbide (SiC): Ideal for high-power and high-temperature environments

Gallium Nitride (GaN): Enables high-frequency and high-efficiency power devices

Critical material properties evaluated through testing include:

Electrical conductivity and resistivity

Thermal stability and heat dissipation

Crystallinity and defect density

Band gap and electronic structure

Mechanical integrity and stress tolerance

Accurate characterization of these properties is essential for optimizing device design and manufacturing processes.

Common Materials Testing Methods in the Semiconductor Industry

Semiconductor materials testing relies on a combination of mechanical, thermal, electrical, and chemical analysis techniques to fully evaluate material behavior.

Mechanical Testing

Evaluates strength, fracture resistance, and durability, particularly important for thin films, wafers, and packaging materials.

Thermal Testing

Measures thermal conductivity, thermal expansion, and heat resistance to ensure device stability under operating conditions.

Electrical Testing

Assesses resistivity, capacitance, and dielectric properties critical for device functionality.

Chemical Analysis

Identifies impurities, contaminants, and compositional variations using techniques such as spectroscopy and chromatography.

Widely used characterization methods include:

X-ray Diffraction (XRD): Determines crystalline structure and phase composition

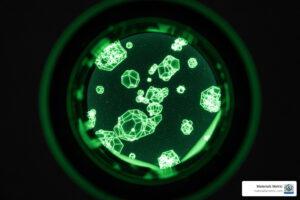

Scanning Electron Microscopy (SEM): Provides high-resolution surface and microstructural analysis

Together, these techniques form the backbone of semiconductor quality control and failure prevention.

Advanced Characterization Techniques for Semiconductor Materials

As device dimensions shrink and material systems become more complex, advanced characterization techniques are increasingly required.

Key advanced techniques include:

Transmission Electron Microscopy (TEM): Atomic-scale imaging of defects, interfaces, and crystal structure

Atomic Force Microscopy (AFM): Nanoscale surface roughness and topography analysis

Raman Spectroscopy: Non-destructive evaluation of molecular structure, stress, and composition

These methods provide deep insight into material behavior that cannot be captured through conventional testing alone, enabling innovation in next-generation semiconductor devices.

Challenges in Modern Semiconductor Materials Testing

Materials testing for modern semiconductors faces growing technical challenges:

Miniaturization: Detecting defects at nanometer scales

Material Diversity: Testing novel materials with unique properties

Environmental Sensitivity: Managing temperature, humidity, and contamination effects

Complex Device Architectures: Multilayer and heterogeneous material systems

Overcoming these challenges requires advanced instrumentation, custom testing protocols, and robust data analysis.

The Role of Data and Analytics in Semiconductor Materials Testing

Data and analytics play a central role in modern semiconductor materials testing. Each test generates large volumes of complex data that must be processed accurately and efficiently.

Data-driven testing supports:

Defect detection and root-cause analysis

Understanding material behavior under varied conditions

Process optimization and yield improvement

Predictive insights for reliability and performance

Advanced analytics transform raw measurements into actionable insights, enabling faster, more confident decision-making across R&D and manufacturing workflows.

How Materials Metric Supports Semiconductor Materials Testing

Materials Metric provides specialized support for semiconductor materials testing through advanced characterization, custom testing workflows, and data-driven analysis.

Our capabilities include:

Advanced materials characterization for semiconductor substrates, thin films, and coatings

Custom testing protocols aligned with specific device and process requirements

Integrated data analysis to support faster interpretation and reporting

Flexible workflows adaptable to R&D, pilot-scale, and production-stage needs

Materials Metric works closely with clients to translate complex testing challenges into reliable, decision-ready data, supporting yield improvement, reliability assurance, and innovation.

Future Trends in Semiconductor Materials Testing

The future of semiconductor materials testing is shaped by increasing complexity and the demand for faster innovation.

Key trends include:

Greater integration of automation and robotics in testing workflows

Use of artificial intelligence and machine learning for defect detection and data interpretation

Development of testing strategies for emerging semiconductor materials

Real-time and in-line materials characterization

As semiconductor technologies evolve, materials testing will continue to play a central role in enabling progress.

Conclusion: Advancing Semiconductor Innovation Through Materials Testing

Materials testing is indispensable to the success of the semiconductor industry. It ensures device reliability, supports innovation, and reduces manufacturing risk in an increasingly demanding technological landscape.

By combining advanced analytical techniques, custom testing strategies, and data-driven insights, Materials Metric supports semiconductor manufacturers and researchers in developing high-performance, reliable devices. As the industry moves forward, precise and adaptable materials testing will remain a cornerstone of semiconductor innovation.