Analytical testing is a foundation of modern science, manufacturing, and product development. It ensures that materials, products, and processes meet strict quality, safety, and regulatory requirements across industries. From pharmaceuticals and medical devices to food, environmental monitoring, and advanced materials, analytical testing provides the data needed to make informed, defensible decisions.

At its core, analytical testing enables precise identification, quantification, and characterization of materials-supporting innovation while reducing risk.

What Is Analytical Testing?

Analytical testing involves the scientific evaluation of a material’s composition, structure, and properties. Using validated laboratory techniques, it confirms identity, purity, concentration, and performance characteristics of substances and products.

Results from analytical testing are essential for:

Verifying material composition

Detecting impurities and contaminants

Supporting product development and optimization

Demonstrating regulatory and quality compliance

Because no single technique answers all questions, laboratories employ a suite of complementary analytical methods based on application needs.

Core Analytical Testing Techniques

Spectroscopy

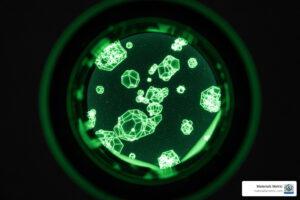

Spectroscopy examines how matter interacts with electromagnetic radiation to reveal chemical structure and composition. It is widely used for material identification, impurity detection, and structural confirmation.

Common spectroscopic techniques include:

Infrared (IR / FTIR) spectroscopy for functional group identification

Nuclear magnetic resonance (NMR) spectroscopy for molecular structure analysis

Ultraviolet–visible (UV-Vis) spectroscopy for concentration and electronic transitions

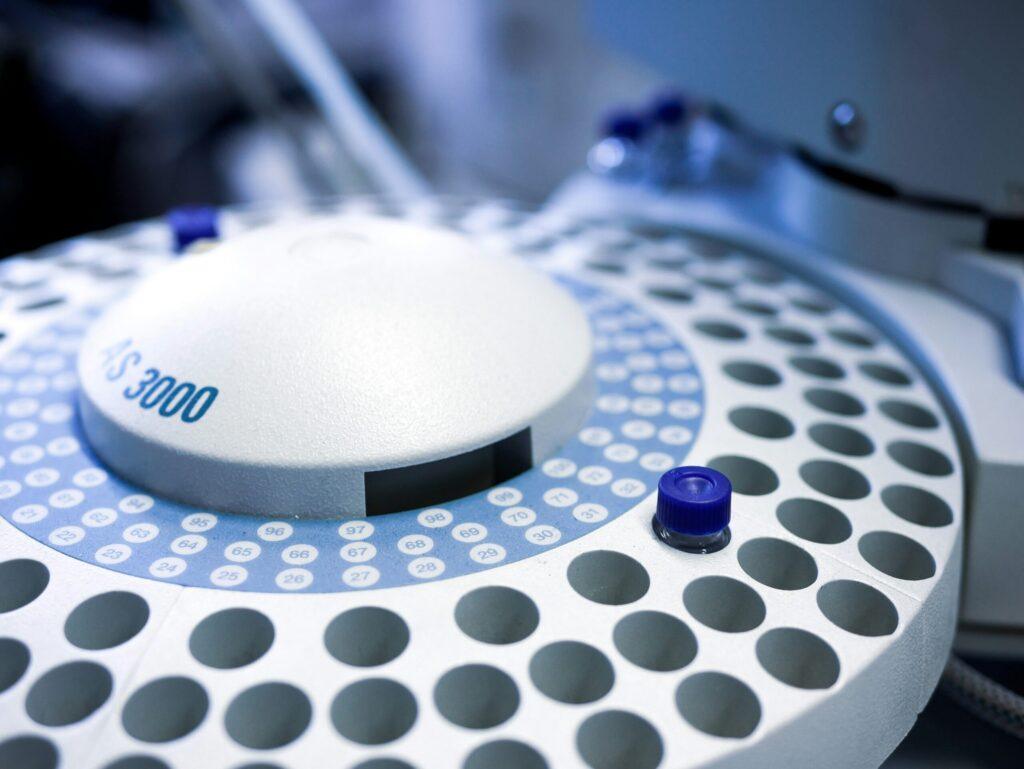

Chromatography

Chromatography separates complex mixtures into individual components, making it indispensable for purity assessment and trace analysis. It is widely used in pharmaceuticals, food testing, and environmental analysis.

Mass Spectrometry

Mass spectrometry provides high sensitivity and specificity, allowing precise determination of molecular weight and composition. When coupled with chromatography, it enables identification of unknown compounds and trace impurities in complex samples.

Together, these techniques form the backbone of modern analytical laboratories.

The Role of Data Analysis in Analytical Testing

Analytical testing does not end with measurement. Data analysis transforms raw signals into meaningful, actionable insights.

Key steps include:

Data acquisition and validation

Data processing and cleaning

Statistical analysis and trend identification

Interpretation against specifications or standards

Advanced software tools are increasingly used to manage large datasets, improve accuracy, and reduce subjectivity. Robust data analysis is critical for ensuring confidence in results, particularly in regulated industries where decisions must be scientifically defensible.

Analytical Testing in Quality Control

Quality control depends on reliable analytical testing to ensure products consistently meet specifications. It plays a critical role in safeguarding safety, efficacy, and performance.

Analytical testing supports quality control by:

Verifying ingredient consistency and formulation accuracy

Detecting contaminants, degradation products, and impurities

Ensuring compliance with regulatory and industry standards

Confirming product performance and stability

Early detection of issues through analytical testing reduces production risk, minimizes recalls, and protects both consumers and brand reputation.

Applications Across Industries

Analytical testing is essential across a wide range of sectors:

Pharmaceuticals and medical devices: Ensuring safety, purity, and performance

Food and beverage: Detecting contaminants, additives, and nutritional components

Environmental monitoring: Analyzing air, water, and soil samples

Manufacturing and materials science: Characterizing raw materials and finished products

Forensics: Supporting evidence analysis and investigations

The versatility of analytical testing allows it to adapt to evolving scientific and industrial challenges.

The Future of Analytical Testing

Advances in technology continue to reshape analytical testing, making it faster, more sensitive, and more data-driven.

Key trends include:

Integration of artificial intelligence and machine learning

Increased laboratory automation

Development of higher-resolution and higher-sensitivity instruments

Real-time data acquisition and analysis

These innovations enhance efficiency, improve data quality, and support faster decision-making—positioning analytical testing as a central driver of future innovation.

Why Analytical Testing Matters

Analytical testing underpins product quality, safety, and regulatory compliance across industries. It enables organizations to innovate with confidence, reduce risk, and meet increasingly complex performance and compliance requirements.

At Materials Metric, analytical testing is performed using rigorous, ISO-aligned workflows and advanced instrumentation to deliver precise, reliable, and actionable data. Our commitment to scientific integrity, customization, and data quality ensures testing solutions that not only meet but exceed industry expectations.

As technologies evolve and materials become more complex, analytical testing will remain indispensable, serving as the scientific foundation for progress, safety, and excellence.