UV–Visible Spectroscopy (UV–Vis)

UV–Visible spectroscopy (UV-Vis) is an analytical technique that measures how molecules absorb light across the ultraviolet and visible wavelength range. Because absorbance is directly related to molecular structure, concentration, and electronic transitions, UV–Vis provides rapid, non-destructive insight into purity, stability, reaction kinetics, and functional behavior in both liquid and solid samples.

At Materials Metric, UV–Vis spectroscopy is applied across materials science, pharmaceuticals, biomaterials, polymers, coatings, and environmental testing. Our workflows deliver reliable absorbance profiles and quantitative data supporting formulation development, quality control, degradation studies, and process monitoring.

Uses of UV–Visible Spectroscopy

UV–Vis enables quantitative and qualitative evaluation of:

- Concentration and purity of analytes

- Electronic transitions and chromophores

- Polymer degradation and oxidation

- Nanoparticle formation, aggregation, and optical properties

- Drug release and dissolution kinetics

- Reaction monitoring and rate determination

- Dye, pigment, and colorant stability

- Biomolecular quantification (proteins, nucleic acids)

It is a valuable tool for both routine QC and advanced research applications.

Applications of UV–Vis Spectroscopy

Pharmaceuticals & Biologics

- API concentration and identity confirmation

- Drug formulation stability

- Dissolution and release profiles

- Protein, DNA, RNA quantification

Nanotechnology & Materials Science

- Nanoparticle size inference from plasmonic peaks

- Monitoring aggregation or degradation

- Characterization of optical materials, dyes, pigments

Polymer & Coating Evaluation

- UV degradation (photo-oxidation) studies

- Colorimetric and optical property measurements

- Tracking curing, crosslinking, or additive leaching

Environmental & Industrial Testing

- Detection of contaminants, nitrates, phosphates, metals (complexed forms)

- Water quality assessments

- Chemical process monitoring

Biomaterials & Medical Devices

- Leachable detection

- Optical clarity, absorption, and coating stability

- Tracking drug-eluting polymer behavior

Sample Analysis Process

1. Sample Submission & Method Scoping

Clients provide information on:

- Sample type (liquid, solid, suspension)

- Expected analyte concentration

- Required sensitivity or regulatory context

2. Sample Preparation

Depending on the material:

- Liquids: Often analyzed directly or diluted

- Solids: Dissolved, dispersed, or measured using integrating spheres

- Nanoparticles: Measured as suspensions to evaluate optical properties

- Polymers/films: Cut into thin sections for transmittance/absorbance

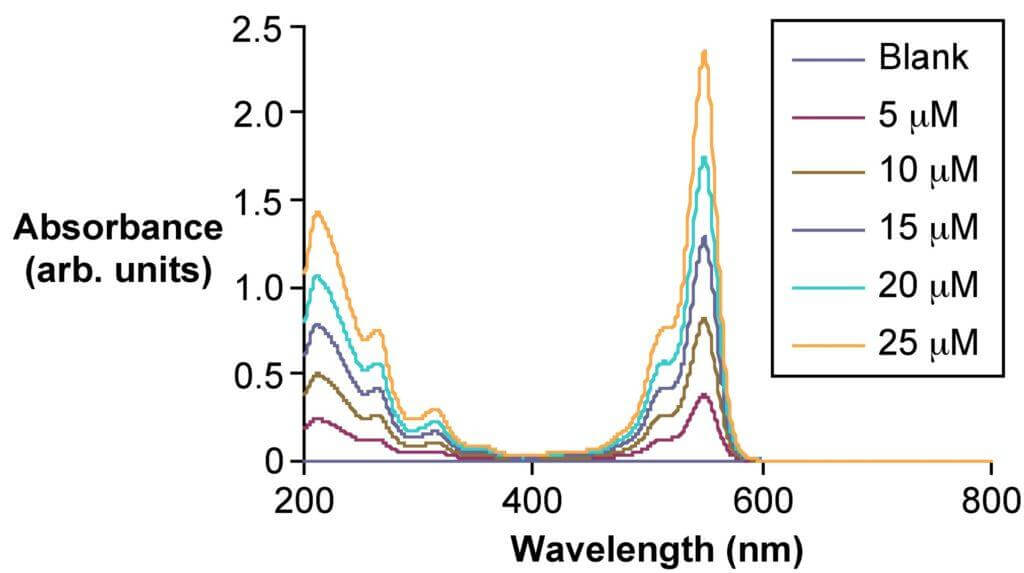

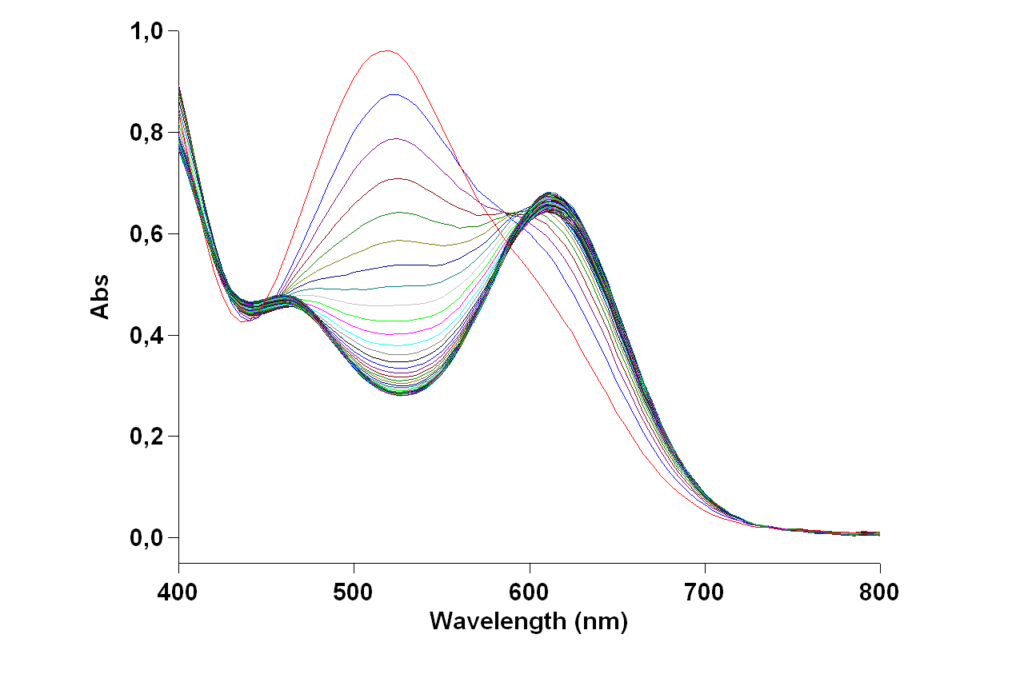

3. UV–Vis Measurement & Data Capture

We obtain:

- Full UV–Vis spectra (190–1100 nm)

- Absorbance curves

- Peak maxima/minima

- Kinetics or time-dependent profiles

4. Data Interpretation & Reporting

Clients receive:

- Spectral plots with annotation

- Quantitative concentration calculations (Beer–Lambert Law)

- Degradation/kinetic analysis if applicable

- Clear conclusions and recommendations

Why Choose Materials Metric for UV–Vis Spectroscopy?

Materials Metric offers high-accuracy UV–Vis testing supported by multidisciplinary expertise in chemistry, polymers, biomaterials, nanotechnology, and pharmaceuticals.

We provide:

- Precise quantitative and qualitative UV–Vis measurement

- Custom method development for complex materials or regulatory needs

- Integrated analysis with FTIR, Raman, HPLC, thermal analysis, and microscopy

- ISO 9001:2015–aligned workflows ensuring reliable, traceable data

- Rapid turnaround with expert interpretation tailored to your application

Whether you are confirming material purity, studying degradation, analyzing nanoparticles, or evaluating coating performance, we deliver clear, actionable insights that accelerate your R&D and quality processes.