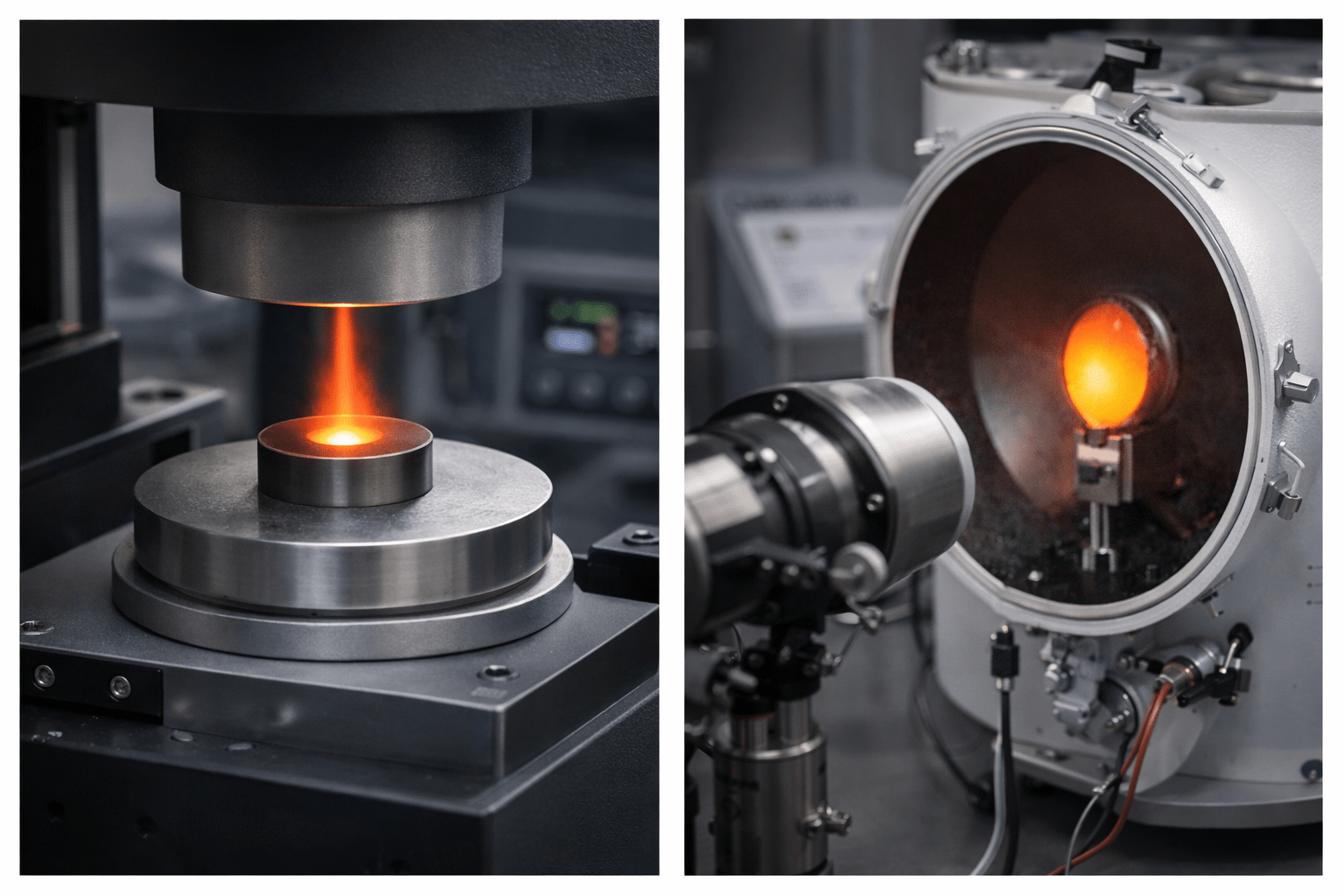

Thermophysical Property Testing

Thermophysical property testing quantifies how materials store, transfer, and radiate heat, as well as how mass and structure influence thermal behavior. These properties govern a material’s response to temperature gradients, heat flux, and thermal cycling, and are fundamental inputs for thermal modeling, energy balance calculations, and performance prediction.

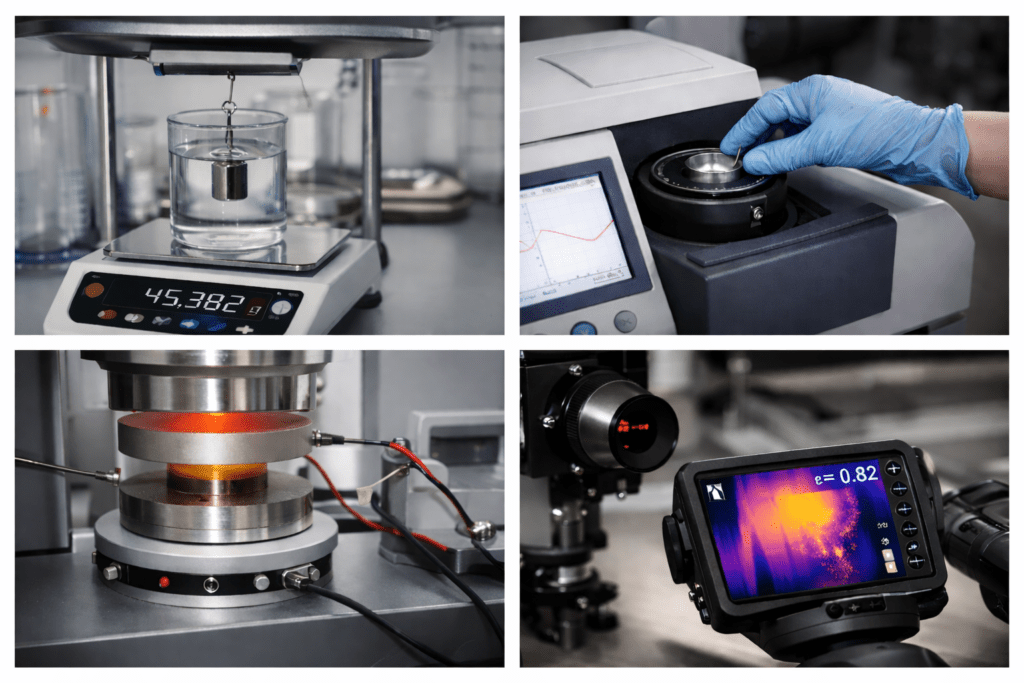

At Materials Metric, thermophysical testing includes measurements of density, specific heat capacity, thermal conductivity, thermal diffusivity, and total hemispherical emissivity, along with related thermal transport and radiative properties. Together, these measurements provide a comprehensive thermal profile essential for advanced materials development, validation, and regulatory support.

Uses of Thermophysical Property Testing

Thermophysical property data are essential for understanding and predicting material behavior under real-world thermal conditions. These measurements are commonly used to:

- Quantify heat storage and heat transfer efficiency

- Support thermal modeling, simulation, and finite element analysis

- Evaluate thermal stability and temperature-dependent performance

- Compare materials for design selection and optimization

- Validate processing conditions, coatings, and thermal treatments

- Generate material property inputs for regulatory and engineering documentation

Materials Metric delivers high-quality, reproducible thermophysical data that directly supports design decisions, modeling accuracy, and risk reduction.

Thermophysical Properties & Tests Covered

Our thermophysical testing services include, but are not limited to:

- Density Measurement – Mass-to-volume relationships critical for thermal modeling, material balance, and structural analysis

- Specific Heat Capacity (Cp) – Heat storage capability across temperature ranges

- Thermal Conductivity – Ability of a material to conduct heat under steady-state or transient conditions

- Thermal Diffusivity – Rate of heat propagation through a material

- Total Hemispherical Emissivity – Radiative heat transfer efficiency, especially critical for high-temperature and aerospace applications

- Temperature-Dependent Property Profiling – Property evolution with temperature or environmental exposure

These properties are often evaluated together to deliver a complete thermophysical dataset.

Applications of Thermophysical Property Testing

Thermophysical testing supports a wide range of industries and use cases, including:

- Aerospace & Defense: Thermal protection systems, coatings, high-temperature composites

- Energy & Power Systems: Insulation materials, battery components, thermal barriers

- Electronics & Thermal Management: Heat sinks, substrates, encapsulants, interface materials

- Advanced Materials & Coatings: Ceramics, polymers, composites, and functional coatings

- Medical Devices & Biomaterials: Temperature-sensitive polymers and implant materials

- Additive Manufacturing: Process optimization and thermal distortion prediction

Accurate thermophysical data enables safer designs, longer service life, and improved system efficiency.

Why Choose Materials Metric for Thermophysical Property Testing

Materials Metric provides scientifically rigorous thermophysical testing integrated with expert interpretation and broader materials characterization capabilities.

What sets us apart:

- Comprehensive thermal property coverage within a single testing strategy

- ISO 9001:2015–aligned workflows ensuring data quality, traceability, and reproducibility

- Integration with thermal analysis, infrared imaging, and computational modeling for deeper insight

- Application-driven testing design, not one-size-fits-all measurements

- Clear, defensible reporting suitable for R&D, engineering validation, and regulatory use

- Collaborative CRO approach, supporting early-stage research through commercialization

By combining thermophysical measurements with chemical, mechanical, optical, and modeling expertise, Materials Metric delivers actionable thermal performance insight, not just raw data.