Micro-Computed Tomography (Micro-CT)

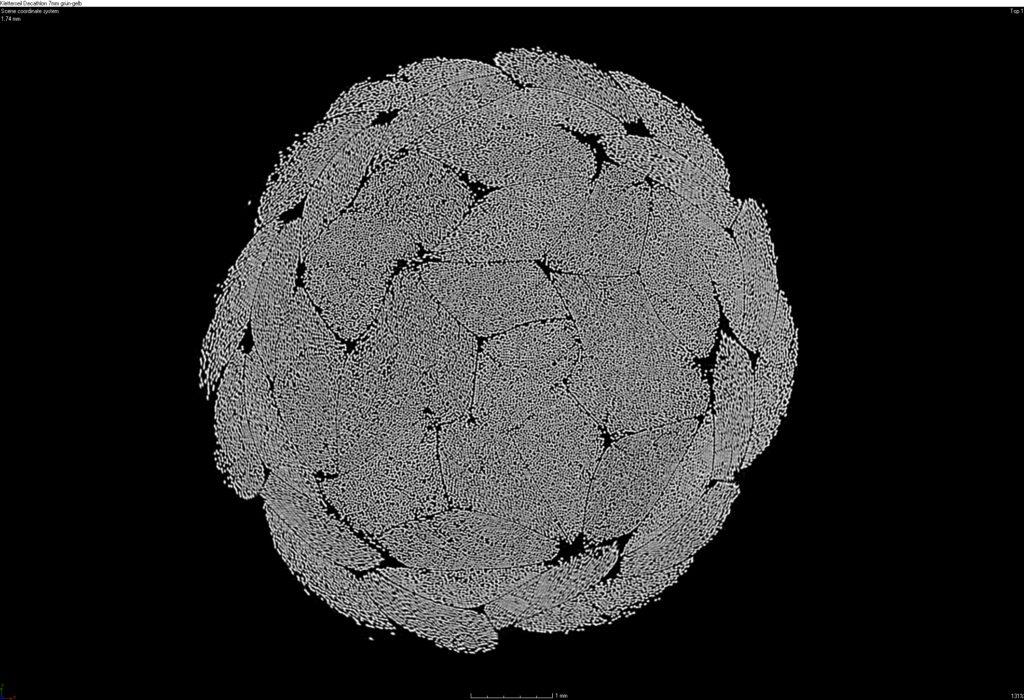

Micro-Computed Tomography (Micro-CT) is a high-resolution, non-destructive 3D imaging technique that uses X-rays to visualize and quantify the internal structure, porosity, density distribution, and micro-architecture of materials and biological systems. By reconstructing the full sample volume into three-dimensional datasets, Micro-CT enables detailed examination of internal features without sectioning or damaging the specimen.

At Materials Metric, Micro-CT is used to analyze internal defects, cracks, voids, interfaces, and spatial organization in biomaterials, tissue scaffolds, additively manufactured components, composites, foams, devices, and engineered materials. This capability is essential for research and development, failure analysis, preclinical studies, additive manufacturing evaluation, and quality control where internal structure directly governs performance and reliability.

Uses of Micro-CT

Micro-CT provides powerful information such as:

- Internal defects (voids, cracks, inclusions)

- Porosity and pore interconnectivity

- Density gradients and structural uniformity

- Layer quality in 3D-printed materials

- Fiber orientation and composite integrity

- Bone structure, mineral density & tissue morphology

- Coating thickness and delamination

- Non-destructive failure analysis

It is one of the most versatile tools for structural evaluation across materials, devices, and biological systems.

Applications of Micro-CT

Biomedical & Preclinical Research

- Bone microarchitecture (trabecular/cortical)

- Biomaterial–tissue integration

- Scaffold porosity & degradation

- Implant fixation and bone ingrowth

- In-vivo or ex-vivo tissue imaging

Medical Devices & Implants

- Internal defects in stents, orthopedic implants, dental materials

- Coating thickness and adhesion assessment

- Assembly verification for multi-component devices

Materials Science & Engineering

- Porosity and density mapping in polymers, composites, ceramics, metals

- Crack propagation and failure mode analysis

- Fiber alignment and filler distribution

- Quality inspection of molded, cast, or sintered materials

Additive Manufacturing (3D Printing)

- Layer-by-layer uniformity

- Porosity, void detection & interlayer adhesion

- Dimensional accuracy and internal geometry validation

Pharmaceutical & Drug Delivery Systems

- Evaluation of drug-loaded scaffolds

- Internal structure of tablets and long-acting delivery implants

- Coating integrity on microcapsules or polymer systems

Sample Analysis Process

1. Sample Submission & Study Design

We review:

- Material type (polymer, ceramic, metal, composite, tissue, scaffold)

- Required voxel resolution

- Analysis goals (porosity, defects, density, structure, integration, etc.)

2. Sample Preparation

Micro-CT is non-destructive, so most samples require minimal preparation.

For optimal results:

- Samples are mounted to minimize movement

- Moisture-sensitive materials may be stabilized or sealed

- Biological tissues may require contrast agents

3. Micro-CT Scanning

High-resolution X-ray imaging generates:

- Full 3D reconstructions

- Slice-by-slice images

- Density maps and internal morphology

4. Image Processing & Quantitative Analysis

We extract:

- Porosity (%), pore size & connectivity

- Defect size & distribution

- Wall thickness and dimensional metrics

- Density gradients

- Fiber orientation maps

- Morphometric parameters for bone or tissue

- 3D visualization models

5. Reporting

Clients receive:

- 3D renderings & volume reconstructions

- Quantitative datasets

- Annotated cross-sectional views

- Interpretations aligned to R&D or regulatory goals

- Recommendations for material or design optimization

Why Choose Materials Metric for Micro-CT?

Materials Metric provides advanced Micro-CT imaging combined with expert interpretation across materials science, biomedical engineering, and device development.

We offer:

- High-resolution 3D imaging with non-destructive workflows

- Integrated analysis using SEM, EDS, XRD, FTIR, mechanical testing & thermal analysis

- Quantitative outputs: porosity, density, defect mapping, morphometry

- ISO 9001:2015–aligned processes for reliable, traceable results

- Cross-disciplinary scientists who understand both material behavior and biological systems

- Tailored protocols for sensitive, complex, or novel materials

- Clear reporting that supports R&D, preclinical evaluation, verification/validation, and regulatory submissions

Our Micro-CT services give you the full internal picture of your material or device—without destroying the sample—enabling precise design, confident troubleshooting, and accelerated development.