Corrosion Testing

Corrosion testing evaluates how materials degrade when exposed to chemical, environmental, electrochemical, or mechanical stressors over time.

Corrosion alters surface chemistry, mechanical strength, coating integrity, and structural reliability, making it a critical factor in product safety and longevity, especially for metals, alloys, coatings, composites, implants, and conductive materials.

Materials Metric provides comprehensive corrosion testing to determine corrosion rate, mechanism, susceptibility, protective coating performance, and long-term durability under controlled, accelerated, or real-world exposure conditions.

Uses of Corrosion Testing

Corrosion testing is essential for determining:

- Material suitability in harsh or reactive environments

- Coating performance and protective barrier effectiveness

- Degradation pathways and failure modes

- Galvanic or electrochemical behavior of multi-material systems

- Long-term stability for regulatory submissions

- Predictive lifetime estimation and risk assessment

Corrosion testing supports product design, material selection, quality assurance, regulatory compliance, and R&D optimization.

Applications of Corrosion Testing

Medical Devices & Implants

- Corrosion resistance of metallic implants (stainless steel, Co–Cr, Ti-based alloys)

- Evaluation of surface treatments, coatings, or passivation layers

- Ion release analysis (Ni, Cr, Co, Ti, etc.)

- Compliance with ISO 10271, ASTM F2129, and FDA expectations

Aerospace, Automotive & Energy

- High-temperature oxidation and corrosion

- Salt spray/Fog testing for marine and outdoor environments

- Corrosion-fatigue and stress-corrosion cracking assessments

- Evaluation of conductive components, fasteners, structural parts

Electronics & Conductive Materials

- Galvanic corrosion between dissimilar metals

- Moisture, humidity, and environmental exposure studies

- Coating durability for circuit boards and housings

Coatings, Polymers & Composites

- Barrier performance and degradation

- Chemical resistance to acids, bases, solvents, and salts

- Permeability and long-term coating integrity

Industrial & Chemical Processing

- Compatibility of materials with harsh chemicals

- Pipeline, tank, and reactor component evaluation

- Accelerated corrosion testing for lifetime prediction

Sample Analysis Process

1. Sample Submission & Test Design

We gather:

- Material type (metal, alloy, coating, polymer)

- Environmental conditions of interest

- Applicable standards (ASTM, ISO, MIL-spec, FDA requirements)

2. Sample Preparation

Depending on material and test type:

- Polishing, cleaning, or surface treatment

- Mounting for electrochemical testing

- Coating thickness and uniformity measurement

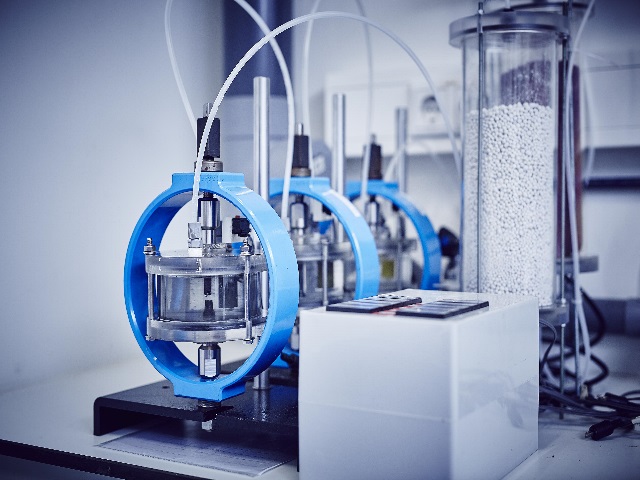

3. Corrosion Exposure & Evaluation

We perform standardized or custom corrosion studies, including:

- Electrochemical corrosion testing (potentiodynamic polarization, EIS)

- Salt spray / salt fog testing (ASTM B117)

- Immersion testing (acidic, alkaline, saline, or biological media)

- Environmental chamber testing (humidity, temperature cycling)

- Galvanic corrosion assessment

- Pitting, crevice, and intergranular corrosion studies

4. Post-Corrosion Characterization

Analytical evaluations include:

- SEM/EDS for surface morphology & corrosion products

- XPS/XRD for chemical state identification

- Weight-loss analysis for corrosion rate

- ICP-MS/OES for metal ion release

- Mechanical property changes (strength, fatigue, hardness)

5. Reporting & Interpretation

Clients receive:

- Detailed corrosion profiles

- Quantitative corrosion rates

- Failure mechanism identification

- Recommendations for materials improvement or coating optimization

Why Choose Materials Metric for Corrosion Testing?

Materials Metric offers multidisciplinary corrosion expertise supported by advanced analytical, mechanical, and surface characterization tools.

We provide:

- Comprehensive electrochemical and environmental corrosion testing

- Integrated analysis (SEM, EDS, XPS, ICP-MS, mechanical testing, thermal analysis)

- Custom study design tailored to your material and operational environment

- ISO 9001:2015–aligned workflows ensuring high-quality, traceable results

- Deep knowledge of metals, coatings, composites, biomaterials, and engineered systems

- Expert interpretation connecting chemical, structural, and mechanical degradation

From early material screening to final regulatory submission, we deliver actionable data that strengthens durability claims and de-risks product development.