Computational Materials Modeling & Simulation

Computational Materials Modeling & Simulation uses advanced mathematical models, physics-based simulations, and data-driven algorithms to predict how materials behave under mechanical, thermal, chemical, and environmental stresses. These methods help researchers understand material performance, optimize formulations, design new materials, and reduce the need for extensive physical prototyping.

By simulating phenomena such as stress–strain behavior, fracture mechanics, diffusion, thermal transitions, degradation, fatigue, corrosion, and molecular interactions, researchers can evaluate performance virtually, accelerating R&D, improving reliability, and reducing material cost and testing time.

Materials Metric integrates finite element analysis (FEA), finite element modeling (FEM), multi-physics simulations, thermal and mechanical modeling, molecular modeling, and degradation simulation, enabling a comprehensive understanding of materials ranging from polymers and composites to metals, ceramics, biomaterials, nanomaterials, and advanced functional materials and predicting material performance before physical testing.

Computational Materials Modeling & Simulation Can Achieve

1. Mechanical Behavior & Failure Prediction

Stress–strain curve simulation

Yield strength, fatigue life, fracture toughness, crack propagation

Predicting deformation, buckling, or creep under load

2. Thermal & Thermodynamic Modeling

Glass transition, crystallization, melting behavior

Heat distribution, thermal conductivity, thermal degradation pathways

Phase diagrams, reaction energetics, and thermal cycling effects

3. Molecular & Microstructural Modeling

Polymer chain dynamics, crystallinity, crosslink density effects

Nanoparticle dispersion and interfacial interactions

Grain boundary behavior, lattice defects, and anisotropy

4. Surface Interaction & Material Interface Modeling

Adhesion, friction, wear, and interfacial bonding

Protein adsorption and biological interface prediction (for biomaterials)

Coating integrity and delamination modeling

5. Diffusion, Transport, & Chemical Kinetics

Moisture absorption, solvent diffusion, or ion transport

Reaction kinetics and degradation pathways

Drug release and diffusion modeling for biomedical materials

6. Multi-Scale Modeling (Atomic → Macro)

Atomistic simulations (MD), microstructure (phase-field), and continuum modeling (FEM)

Integration of nanoscale features with macroscale performance predictions

Applications

Advanced Materials & Polymers

Predict mechanical strength, elasticity, viscoelastic behavior

Model polymer curing, degradation, and recyclability

Optimize blends, additives, and stabilizers

Medical Devices & Biomaterials

Simulate implant–tissue interactions

Predict wear, fatigue, and surface degradation over time

Evaluate device performance prior to preclinical studies

Energy & Aerospace Materials

Thermal tolerance and heat shielding simulation

Corrosion, oxidation, and high-temperature mechanical behavior

Modeling composite structures for lightweight performance

Nanomaterials & Functional Surfaces

Modeling nano-patterned surfaces, coatings, and thin films

Predict optical, electronic, or catalytic properties

Evaluate nano–bio interactions (e.g., nanoparticles, sensors)

Pharmaceutical & Controlled Release Systems

Drug diffusion, dissolution, and release modeling

Stability, crystallinity, and moisture interaction prediction

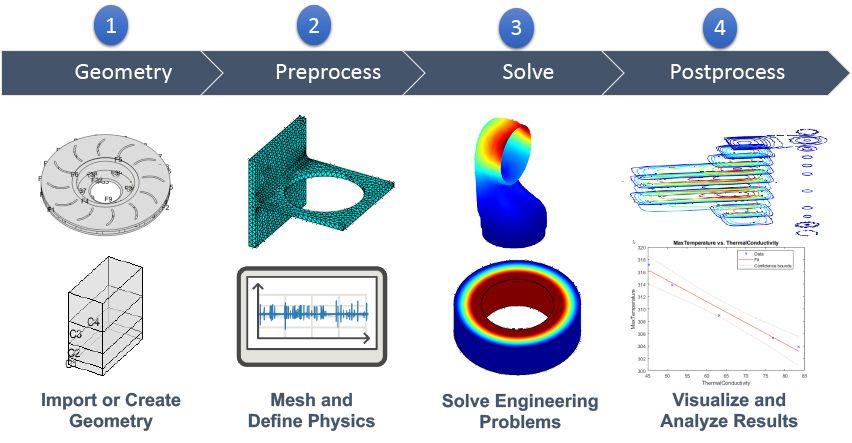

Computational Materials Modeling Workflow

1. Problem Definition & Data Intake

We identify target properties, environmental conditions, and performance criteria.

We gather material data from literature, experiments, or client datasets.

2. Model Selection & Setup

Selection of FEM, molecular modeling, thermodynamic models, or hybrid multi-scale approaches.

3. Simulation Execution

Mechanical simulation (static/dynamic loading)

Thermal, diffusion, or kinetics modeling

Atomistic or microstructural simulation

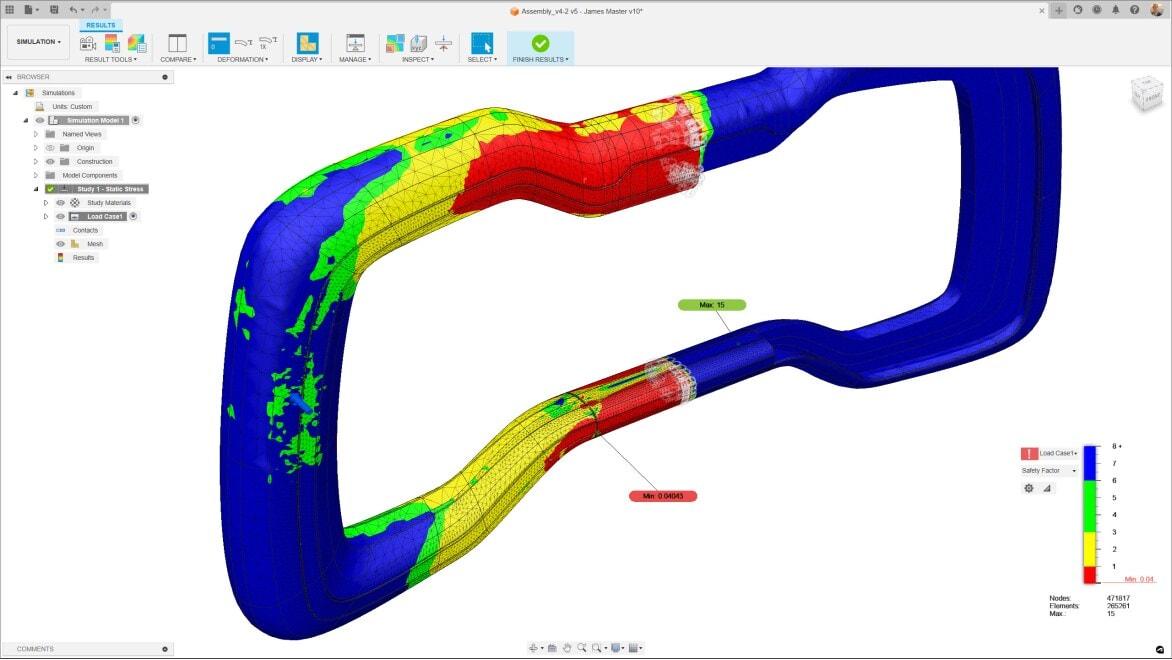

4. Post-Processing & Visualization

Generation of heat maps, contour plots, force distributions, molecular trajectories, and stress profiles.

5. Interpretation & Reporting

We provide a clear, structured summary including:

Key performance predictions

Failure risks

Recommended material modifications

Design optimization strategies

6. Integration With Experimental Data

Simulation results are paired with empirical testing (DSC, TGA, DMA, mechanical testing, spectroscopy) for validation and refinement.

Why Choose Materials Metric

Materials Metric offers a unique blend of computational modeling expertise and deep experimental capabilities, allowing us to ground simulations in real-world material behavior.

We provide:

ISO 9001:2015–aligned quality processes ensuring reliable, reproducible analytics

Cross-disciplinary scientific expertise spanning materials science, chemistry, biomaterials, simulation physics, and biomedical engineering

Multi-scale modeling capabilities, from atomic simulations to structural FEM

Seamless integration with laboratory testing including thermal, mechanical, spectroscopic, and surface analysis

Custom simulation solutions for complex materials, coatings, devices, and biomedical systems

Regulatory-supportive documentation suitable for design verification, risk assessment, and submission packages

Our simulations reduce development time, enhance design accuracy, and help companies innovate confidently.

Related services