BET Surface Area & Porosity Analysis

BET (Brunauer–Emmett–Teller) Surface Area & Porosity Analysis is a gas adsorption–based technique used to quantitatively measure the specific surface area of materials by evaluating the amount of adsorbate gas retained on the material surface. Porosity analysis extends this capability to characterize pore volume, pore diameter, and pore size distribution, encompassing micro-, meso-, and macroporous structures.

At Materials Metric, BET analysis provides critical insight into surface reactivity, adsorption capacity, permeability, and structural accessibility, which directly govern the performance of catalysts, porous polymers, ceramics, composites, powders, and biomaterials. These measurements are essential for material design, formulation optimization, quality control, and performance prediction in applications where surface-driven behavior determines functional outcomes.

Use of BET Surface Area & Porosity Analysis

BET and porosity testing are used to:

• Determine the true accessible surface area of powders and porous materials

• Characterize pore structure for adsorption, filtration, or catalytic behavior

• Compare batch-to-batch consistency

• Evaluate the impact of processing, activation, or sintering

• Support R&D for engineered porous materials

• Identify structural changes after thermal, chemical, or mechanical treatment

Applications

- Catalysts & Adsorbents: activity and capacity linked to surface area

- Battery Materials: cathode/anode powders, carbon materials, metal oxides

- Biomaterials & Scaffolds: porosity for cellular infiltration and fluid flow

- Ceramics & Zeolites: pore architecture and adsorption sites

- Activated Carbon & Char Materials: filtration and purification performance

- Polymer Foams & Porous Composites: structural uniformity

- Nanomaterials: nanopores, high-surface-area powders

Sample Analysis Process

1. Submission & Objective Review

- Identify analysis goals (surface area, porosity, pore-size distribution)

- Provide sample type (powder, pellet, granule, foam, scaffold)

- Confirm any temperature limitations or sensitivity

2. Sample Preparation

- Samples undergo controlled degassing to remove moisture or volatile contaminants

- Degassing temperature/time customized for each material

- Conditions carefully selected to avoid altering delicate structures

3. BET & Porosity Measurement

Gas adsorption is performed using nitrogen or other suitable adsorbates:

- Adsorption/desorption isotherms collected over multiple pressure points

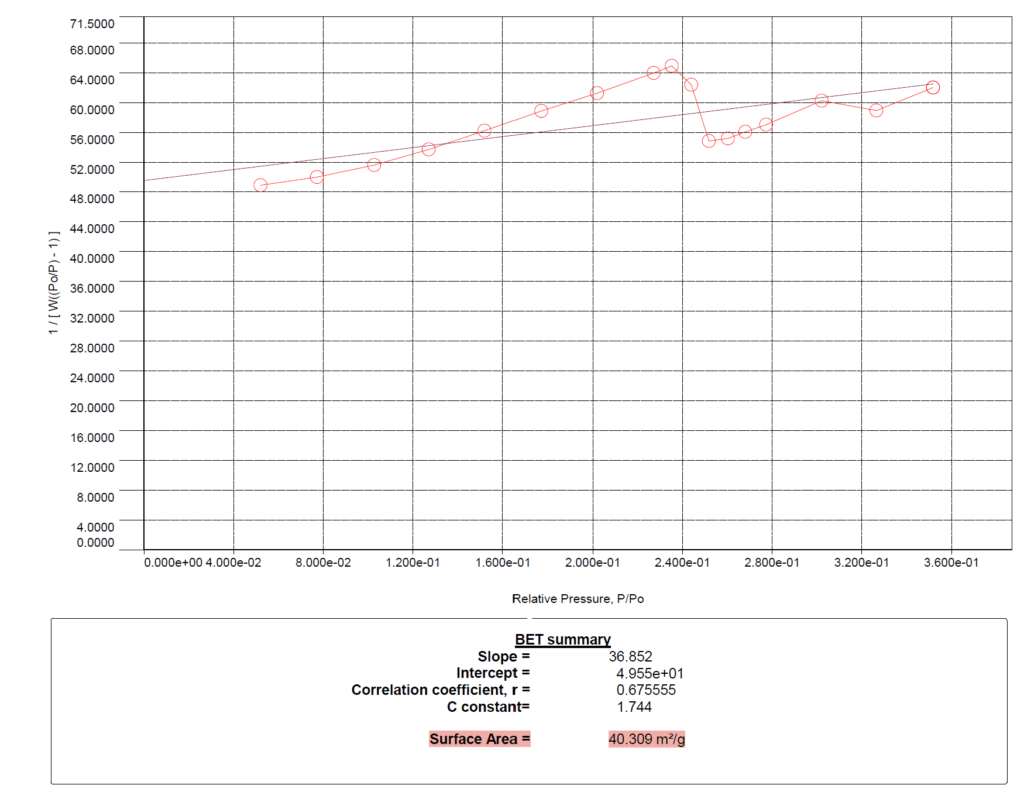

- BET model applied to determine specific surface area (m²/g)

- BJH or DFT analysis used for pore-size distribution

- Micropore and mesopore characterization performed as needed

4. Data Processing & Reporting

- BET surface area (single-point and multipoint values)

- Pore volume and pore-size distribution

- Adsorption/desorption isotherm curves

- Micropore and mesopore fraction (if applicable)

- Interpretation linked to material performance, adsorption capacity, or structural engineering

Why Choose Materials Metric for BET & Porosity Analysis

Materials Metric delivers high-precision gas adsorption analysis combined with materials science expertise across nano-, micro-, and macro-porous systems.

Our BET services offer:

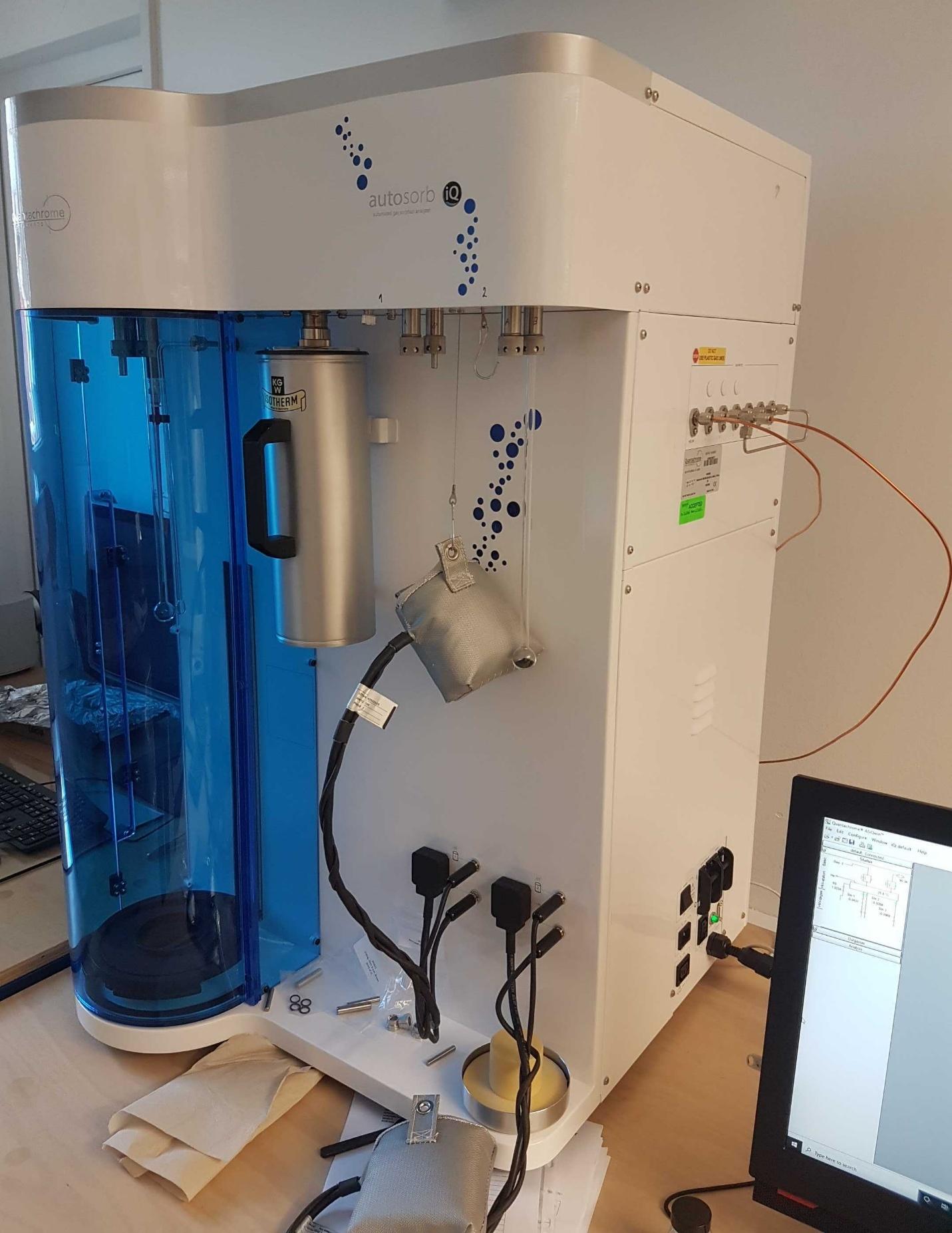

- Accurate surface area and porosity measurements using advanced adsorption systems

- Custom degassing and preparation tailored to sensitive biomaterials or nano-powders

- Expertise in catalysts, biomaterials, energy materials, polymers, and ceramics

- Integration with particle sizing, SEM, and chemical analysis for complete material profiles

- Clear, publication-ready reporting with actionable interpretation for R&D and manufacturing

We help you understand how surface area and pore structure influence reactivity, adsorption, dissolution, mechanical behavior, and overall material performance.