Rheology & Viscoelastic Testing

Rheology and viscoelastic testing examine how materials flow, deform, and respond to applied stress or strain over time. Unlike conventional mechanical tests, these techniques are specifically designed for soft and complex materials where time-, temperature-, and frequency-dependent behavior governs real-world performance.

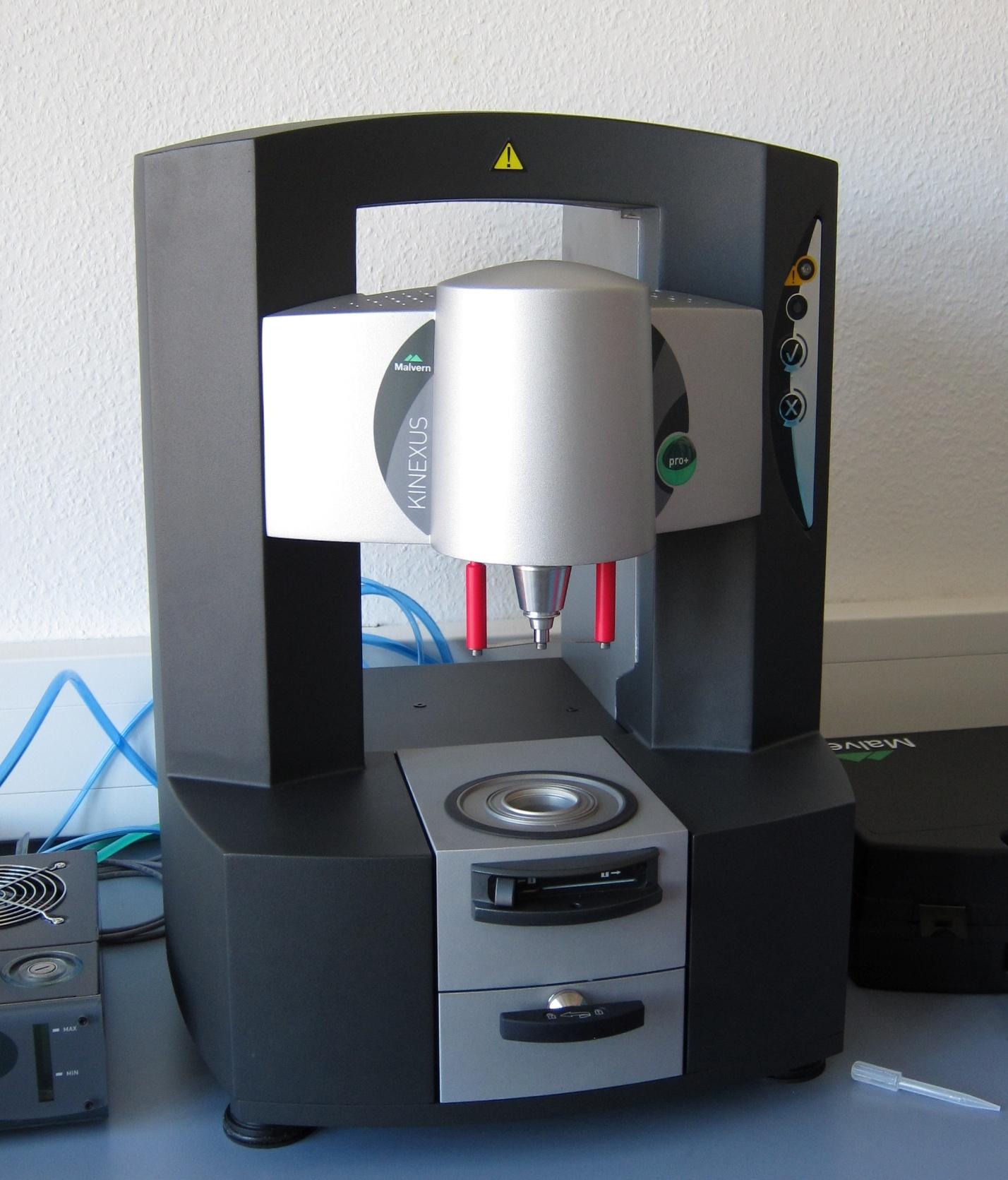

At Materials Metric, rheology and viscoelastic testing are used to characterize liquids, pastes, gels, hydrogels, slurries, polymer melts, and biological materials. Using precision rheometers, we measure viscosity, viscoelastic moduli, yield stress, gelation behavior, and flow characteristics that control processing, dispensing, injection, extrusion, and functional performance.

Use of Rheology & Viscoelastic Testing

Rheological testing is used to:

• Characterize viscosity under varying shear rates

• Determine viscoelastic properties (storage modulus G′, loss modulus G″)

• Evaluate gelation, curing, or crosslinking behavior

• Measure yield stress and flow initiation behavior

• Assess thixotropy and time-dependent viscosity recovery

• Compare pre- and post-aging thermal or chemical stability

• Optimize material flow in processing, mixing, extrusion, or injection systems

Applications

- Biomaterials & Hydrogels: gel stiffness, viscoelasticity, crosslinking behavior

- Polymer Melts & Resins: melt viscosity, processing stability

- Medical Devices: injectable hydrogel flow properties, drug delivery formulations

- Pharmaceuticals: suspension stability, cream/ointment rheology

- Food & Agriculture: consistency, flow behavior, yield stress

- Inks, Coatings & Adhesives: printability, leveling, curing dynamics

- Cosmetics & Personal Care: texture, spreadability, temperature stability

- Slurries & Pastes: flow and settling behavior

Sample Analysis Process

1. Submission & Objective Definition

- Identify material type (gel, polymer melt, liquid, slurry, etc.)

- Define testing goals: viscosity, viscoelasticity, gelation, temperature effects

- Select desired shear or oscillation measurement types

2. Sample Preparation

- Samples loaded onto parallel plate or cone–plate geometry based on viscosity

- Temperature set according to material requirements

- Hydrogels maintained in hydrated and controlled environments

- Polymer melts or resins pre-conditioned for testing temperature

3. Rheological Testing

We perform the appropriate combination of rheological methods:

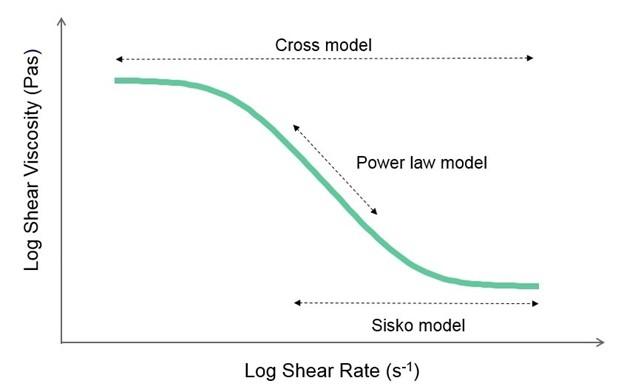

Steady-Shear Measurements

- Viscosity vs. shear rate

- Shear-thinning or shear-thickening behavior

Oscillatory Rheology

- Storage modulus (G′) and loss modulus (G″)

- Frequency sweeps (viscoelastic fingerprints)

- Amplitude sweeps (linear viscoelastic region)

- Gelation and curing kinetics

Yield Stress & Thixotropy

- Flow initiation behavior

- Time-dependent viscosity recovery

4. Data Processing & Reporting

- Viscosity curves and flow behavior classification

- G′/G″ viscoelastic plots

- Tan δ analysis (solid-like vs. liquid-like behavior)

- Gelation or curing trend graphs

- Yield stress and thixotropy indices

- Clear interpretation connected to your processing or product goals

Why Choose Materials Metric for Rheology & Viscoelastic Testing

Materials Metric provides precision rheological analysis backed by deep expertise in polymers, biomaterials, hydrogels, slurries, coatings, and formulation science.

We offer:

- Wide-range rheometry for liquids, gels, melts, and semi-solids

- Oscillatory and steady-shear testing for viscoelastic profiling

- Temperature-controlled rheology for formulation, curing, and processing studies

- Expertise in interpreting rheological data for real-world performance

- Integration with chemical analysis, microscopy, and mechanical testing for comprehensive characterization

- Detailed, publication-ready reporting tailored to R&D, QC, and regulatory needs

We help you understand how your material flows, deforms, and behaves—in manufacturing, biological environments, and end-use conditions.

Related services

- Dynamic Mechanical Analysis (DMA)

- Tensile, Compression & Shear Testing

- Surface Roughness & Adhesion Testing

- Chemical & Analytical Testing

- Thermal, Infrared & Optical Analysis