Infrared Thermography (IR Imaging)

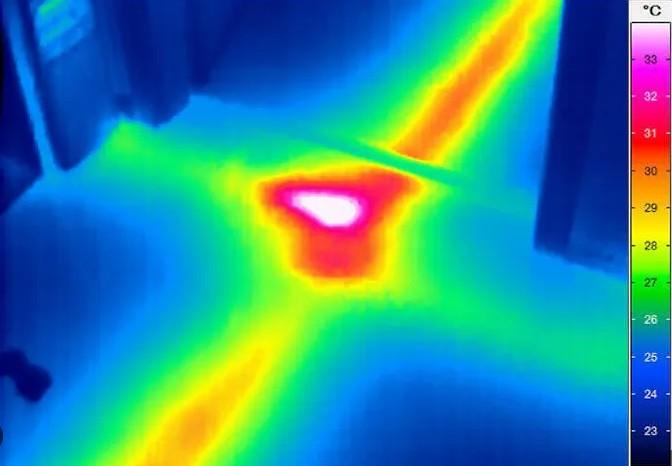

Infrared Thermography (IR imaging) is a non-contact, non-destructive technique that uses infrared sensors to detect and map temperature variations across the surface of a material or component. By visualizing thermal patterns in real time, IR imaging reveals how heat is distributed and dissipated under operational or loading conditions.

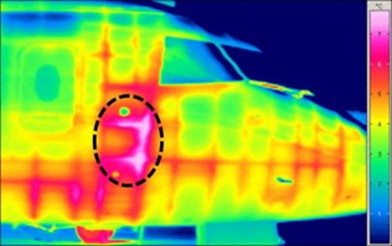

At Materials Metric, infrared thermography is applied to evaluate thermal gradients, surface temperature distribution, hotspots, and uneven heating, as well as to detect defects such as voids, delamination, or subsurface inconsistencies. This technique is widely used in materials research, electronics, composites, medical devices, and manufacturing to assess thermal performance, process reliability, and structural integrity.

Use of IR Thermography

IR imaging helps researchers and engineers:

• Identify thermal anomalies and defects

• Monitor heating or cooling behavior

• Evaluate coating or adhesive uniformity

• Detect subsurface voids or delamination

• Assess thermal insulation performance

• Analyze electronic components for overheating

Applications of IR Thermography

- Composites & Laminates: delamination, crack zones

- Electronics: thermal hotspots, component failure

- Medical Devices: thermal distribution under load

- Coatings & Films: curing uniformity, heat response

- Construction Materials: insulation and thermal leakage

Sample Analysis Process

1. Submission & Objective Review

- Define analysis temperature, heat source, and measurement goals

- Identify material type to set correct emissivity values

2. Sample Preparation

- No dissolution, no cutting required unless size reduction is needed

- Surfaces cleaned to improve emissivity consistency

- Dark matte coatings applied if needed to reduce reflectivity

- Samples positioned on stabilized platform

3. IR Imaging

- Real-time thermal imaging during heating/cooling

- Controlled heat-source application if required

- Temperature gradients and distribution monitored

4. Data Processing & Reporting

- High-resolution thermal maps

- Temperature profiles and hotspot identification

- Identification of thermal defects, non-uniformity, or instability

- Application-specific interpretation

Why Choose Materials Metric for Your IR Imaging

Materials Metric provides high-sensitivity thermal imaging that uncovers hidden material defects and performance limitations.

Our IR imaging services offer:

- High-resolution thermal cameras for precise mapping

- Expertise with polymers, composites, coatings, electronics, and medical materials

- Non-contact imaging ideal for delicate or temperature-sensitive components

- Defect detection including hotspots, delamination, and voids

- Clear thermal reports used for R&D, quality assurance, and failure analysis

We convert thermal data into actionable insights that guide product design and reliability decisions.