Thermo-Mechanical Analysis (TMA)

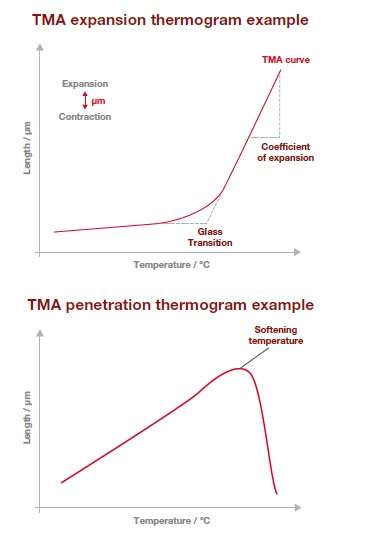

Thermo-Mechanical Analysis (TMA) evaluates how a material expands, contracts, or deforms in response to controlled temperature changes under an applied mechanical load. By measuring dimensional changes as a function of temperature or time, TMA provides quantitative insight into thermo-mechanical behavior that directly affects material performance.

At Materials Metric, TMA is used to determine coefficient of thermal expansion (CTE), softening point and glass transition behavior, dimensional shrinkage or swelling, film thickness and indentation response, and creep or stress-relaxation under thermal conditions. These measurements are essential for materials used in high-precision, temperature-sensitive applications, including polymers, coatings, composites, electronic materials, and advanced engineering systems.

Use of TMA

TMA helps researchers and engineers:

• Measure thermal expansion and contraction

• Analyze dimensional stability of polymers, films, composites, and laminates

• Determine softening or glass transition temperatures

• Evaluate creep behavior under load at elevated temperatures

• Assess thermal mismatch between layered or bonded structures

• Predict material performance in end-use thermal environments

Applications of TMA

- Polymers & Plastics: CTE, Tg, dimensional changes

- Composites & Laminates: mismatch and shrinkage analysis

- Medical Devices: thermal-induced deformation

- Electronics: multilayer thermal compatibility

- Coatings & Films: thickness, penetration, softening behavior

Sample Analysis Process

1. Submission & Objective Review

- Define test goals (expansion, penetration, creep, softening)

• Select appropriate probe mode (expansion, penetration, tension, compression)

• Establish heating/cooling rates and temperature ranges

2. Sample Preparation

- Samples are tested as solid pieces, never dissolved

• Cut to precise dimensions according to probe mode

• Surfaces trimmed for flat, parallel contact

• Soft materials may require controlled drying or conditioning

• Films carefully cut to avoid edge defects

3. TMA Testing

- Controlled temperature scan with dimensional change measurement

• Optional load for creep analysis

• Data collected continuously for high-resolution dimensional tracking

4. Data Processing & Reporting

- CTE values

• Softening temperature and Tg

• Dimensional-change graphs

• Interpretation aligned with material performance and engineering requirements

Why Choose Materials Metric for Your TMA Analysis

Materials Metric provides high-precision thermal-mechanical characterization with an engineering-driven approach.

Our TMA services offer:

• Accurate CTE measurements for design and qualification

• Sensitive softening and Tg analysis using probe-based detection

• Custom testing for films, foams, laminates, composites, and medical materials

• Creep and dimensional-stability testing under realistic loads

• Clear interpretation connecting results to material reliability, product performance, and thermal compatibility

We turn dimensional data into precise engineering insights for R&D, product design, and regulatory support.