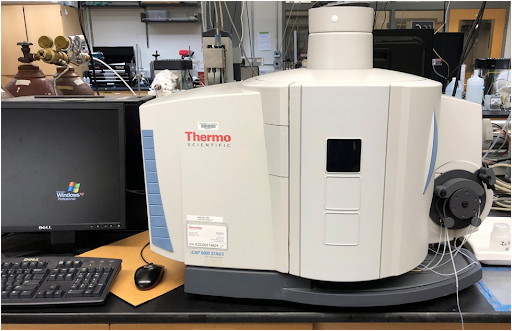

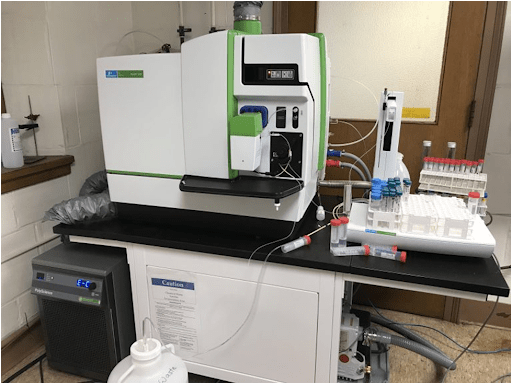

Inductively Coupled Plasma (ICP–OES / ICP–MS)

Inductively Coupled Plasma (ICP) spectroscopy is an advanced analytical approach for precise multi-elemental analysis across a wide concentration range. Using a high-temperature argon plasma (≈10,000 K), samples are atomized and ionized, enabling simultaneous detection of multiple elements with high accuracy and sensitivity.

It is available in 2 forms:

1) ICP–OES (Optical Emission Spectroscopy):

Detects light emitted by excited atoms in a plasma. Ideal for ppm-level quantification across a broad elemental range.

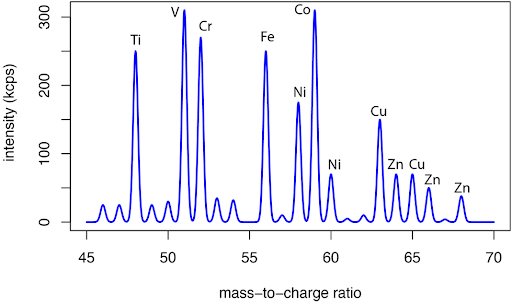

2) ICP–MS (Mass Spectrometry):

Detects charged ions using a mass spectrometer. Provides ppb–ppt sensitivity, making it one of the most powerful tools for ultra-trace metal analysis.

At Materials Metric, both ICP–OES and ICP–MS are applied based on analytical requirements. Together, these techniques support metals characterization, impurity profiling, contamination assessment, and regulatory compliance across polymers, biomaterials, pharmaceuticals, environmental samples, and advanced materials.

Use of ICP–OES / ICP–MS

These methods are used to:

• Detect and quantify trace metals in polymers, biomaterials, coatings, fluids, and environmental samples

• Measure metal leaching from medical devices, implants, and packaging

• Verify alloy composition and elemental purity

• Screen for contamination or toxic metals

• Support extractables &leachables (E&L) studies

• Determine catalyst residues in chemical and polymer synthesis

• Perform full multi-element profiling of complex materials

Applications of ICP–OES / ICP–MS

ICP-based analysis is essential in:

• Biomaterials & Medical Devices: metal ion release, ISO 10993 chemical characterization

• Polymers & Composites: trace catalysts, fillers, and contamination profiling

• Pharmaceuticals: elemental impurities (ICH Q3D compliance)

• Environmental: water, wastewater, soil metal levels

• Metals & Alloys: compositional verification

• Ceramics & Glass: elemental constituents and trace contaminants

• Industrial Chemicals: raw material purity and quality control

Sample Analysis Process

1. Sample Submission & Objective Review

- Identify required analytes (e.g., Al, Fe, Ni, Cr, Pb, Cd, Ti, etc.)

• Determine detection limits (ppm vs. ppb)

• Select ICP–OES or ICP–MS based on sensitivity needs

2. Sample Preparation

Preparation varies by material:

- Acid digestion for solids, biomaterials, polymers, metals, and ceramics

• Dilution for aqueous samples

• Filtration to remove particulates

• Microwave digestion for difficult matrices

3. ICP–OES / ICP–MS Measurement

- Samples introduced into argon plasma

• Ionization and emission/ion detection

• Multi-element quantification in a single run

• Interference correction and calibration

4. Data Processing & Reporting

- Concentrations reported in ppm/ppb

• Full elemental profile

• Calibration validation and QA/QC

• Interpretation based on standards or specifications

Why Choose Materials Metric for Your ICP Analysis

Materials Metric provides high-accuracy multi-element analysis with advanced ICP–OES and ICP–MS capabilities.

We offer:

- Ultra-trace detection (ppb–ppt) with ICP–MS

• Robust ppm-level quantification with ICP–OES

• Expert sample digestion for polymers, biomaterials, ceramics, and metals

• Comprehensive multi-element screening in a single analysis

• Compliance-ready reporting (ISO 10993, ICH Q3D, ASTM, EPA, FDA expectations)

• Specialized workflows for medical devices, extractables/leachables, and contamination studies

• Clear, annotated reports designed for R&D, regulatory, and quality assurance purposes

By integrating ICP results with AAS, XRF, XRD, GC–MS, and chemical characterization, Materials Metric delivers a complete understanding of elemental composition, purity, and metal release behavior.