Understanding Non-Destructive Material Testing Methods: Comprehensive Guide to Techniques and Applications

By Materials Metric

Non-destructive testing (NDT) methods are essential for evaluating the integrity of materials without causing damage. These techniques are crucial in industries such as aerospace, automotive, manufacturing, and research and development, where material reliability is paramount. This comprehensive guide, brought to you by Materials Metric, will explore various non-destructive material testing methods, their applications, and the advantages they offer. Readers will gain insights into how these methods work, the types of flaws they can detect, and the standards governing their use. By understanding these techniques, professionals can ensure quality control and compliance in high-stakes environments. The article will cover ultrasonic testing, radiographic inspection, magnetic particle testing, eddy current testing, visual inspection, and relevant industry standards.

What Are the Main Types of Non-Destructive Testing Methods?

Non-destructive testing methods encompass a variety of techniques designed to assess material properties without causing any harm. The main types of NDT methods include:

- Ultrasonic Testing: Utilizes high-frequency sound waves to detect internal flaws.

- Radiographic Inspection: Employs X-rays or gamma rays to visualize the internal structure of materials.

- Magnetic Particle Testing: Identifies surface and near-surface defects in ferromagnetic materials.

- Eddy Current Testing: Uses electromagnetic induction to detect flaws in conductive materials.

- Visual Inspection: Involves examining materials and components for visible defects.

These methods are integral to maintaining quality and safety across various industries, ensuring that materials meet stringent standards.

How Does Ultrasonic Testing Detect Material Flaws?

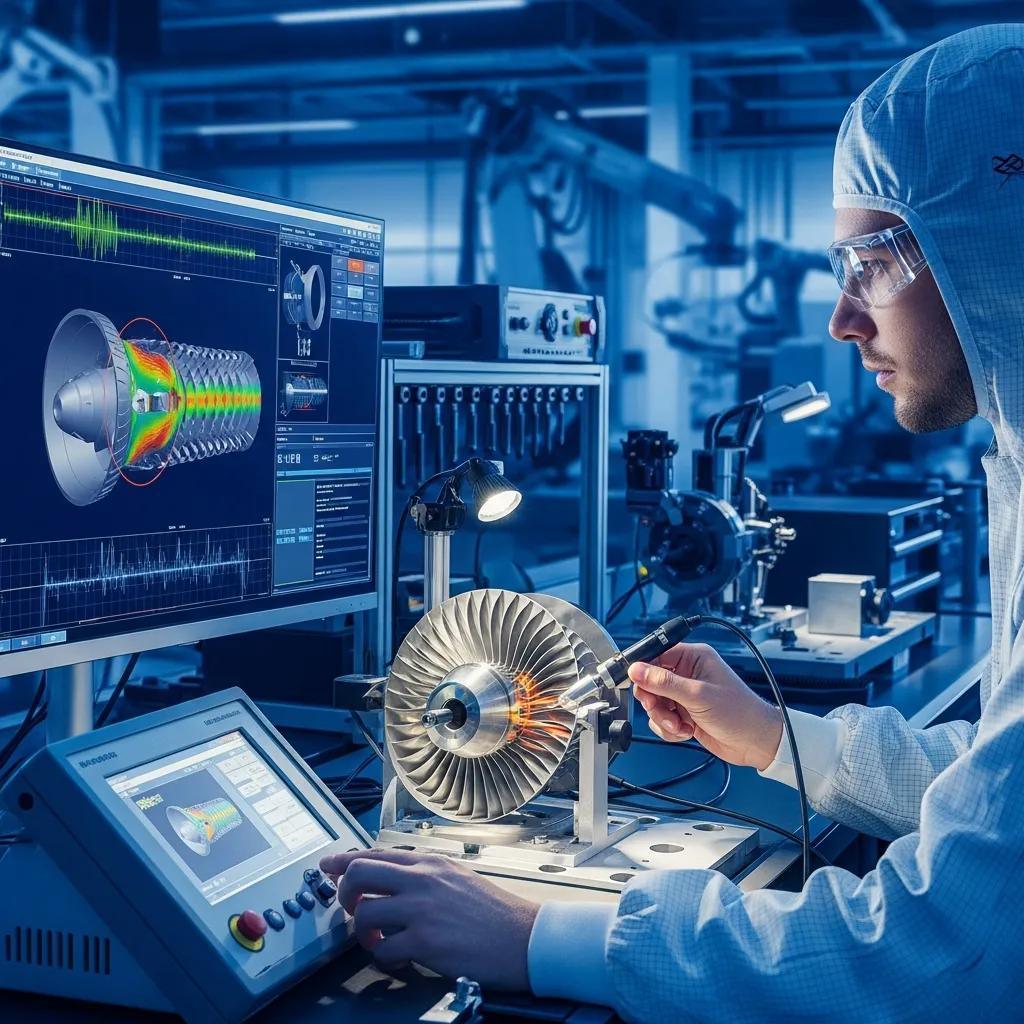

Ultrasonic testing (UT) detects material flaws by sending high-frequency sound waves through the material. When these waves encounter a flaw, such as a crack or void, they are reflected back to the transducer, which converts them into electrical signals. The time it takes for the waves to return helps determine the size and location of the defect. UT is particularly effective for detecting internal flaws in metals, plastics, and composites, making it widely used in aerospace, automotive, and manufacturing industries.

What Are the Principles of Radiographic Inspection?

Radiographic inspection (RI) relies on penetrating radiation, such as X-rays or gamma rays, to create images of the internal structure of materials. The basic principle involves directing radiation through the material onto a photographic film or digital detector. Denser areas of the material absorb more radiation, resulting in a contrast that reveals internal defects. RI is commonly used in weld inspections, casting evaluations, and structural integrity assessments, providing a clear view of potential issues that may not be visible externally.

How Is Magnetic Particle Testing Used for Material Flaw Detection?

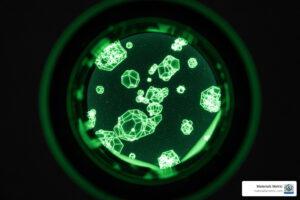

Magnetic particle testing (MPT) is a non-destructive method used to detect surface and near-surface defects in ferromagnetic materials. The process involves magnetizing the material and applying ferromagnetic particles, which can be dry or suspended in a liquid. When a flaw is present, the magnetic field is disrupted, causing the particles to accumulate at the defect site, creating a visible indication. MPT is effective for identifying cracks, laps, seams, and other discontinuities, making it a valuable tool in manufacturing and maintenance operations.

Which Defects Can Magnetic Particle Testing Identify?

Magnetic particle testing can identify several types of defects, including:

- Surface Cracks: Visible discontinuities on the surface of the material.

- Near-Surface Defects: Flaws located just below the surface, such as subsurface cracks.

- Laps and Seams: Defects resulting from improper welding or manufacturing processes.

What Are the Best Practices for Magnetic Particle Inspection?

To ensure effective magnetic particle inspection, several best practices should be followed:

- Surface Preparation: Clean the surface thoroughly to remove contaminants that may interfere with particle adherence.

- Proper Magnetization: Use the appropriate magnetization technique to ensure a strong magnetic field.

- Particle Selection: Choose the right type of magnetic particles based on the inspection requirements.

Following these practices enhances the reliability of MPT results and helps identify defects accurately.

What Are the Advantages and Limitations of Eddy Current Testing?

Eddy current testing (ECT) is a versatile non-destructive testing method that uses electromagnetic induction to detect flaws in conductive materials. The primary advantages of ECT include:

- Sensitivity to Small Defects: ECT can detect very small cracks and corrosion.

- No Contact Required: The method can be performed without direct contact with the material, making it suitable for delicate components.

- Rapid Testing: ECT provides quick results, allowing for efficient inspections.

However, there are limitations to consider:

- Material Limitations: ECT is primarily effective on conductive materials and may not be suitable for non-conductive substances.

- Surface Condition Sensitivity: The presence of surface coatings, roughness, or geometry variations can affect the accuracy of the results.

How Does Eddy Current Testing Apply to Conductive Materials?

Eddy current testing is particularly effective for conductive materials, such as metals and alloys. The method works by inducing eddy currents in the material through an alternating magnetic field. When a flaw is present, it disrupts the flow of these currents, leading to measurable changes in impedance. This technique is widely used in aerospace, automotive, and manufacturing industries for detecting surface cracks, corrosion, and other defects.

What Are Common Use Cases in Industry for Eddy Current Testing?

Eddy current testing is employed in various industries for several applications, including:

- Aerospace: Inspecting aircraft components for fatigue cracks and corrosion.

- Automotive: Evaluating the integrity of critical parts, such as engine components and welds.

- Manufacturing: Ensuring quality control in the production of metal parts and assemblies.

These use cases highlight the importance of ECT in maintaining safety and reliability in high-stakes environments.

How Are Visual Inspection Procedures Conducted Effectively?

Visual inspection is a fundamental non-destructive testing method that involves examining materials and components for visible defects. This technique is often the first step in quality control processes and can be performed using the naked eye or with the aid of magnifying tools. Effective visual inspection requires a systematic approach to ensure thorough evaluations.

What Are Standard Visual Inspection Techniques and Tools?

Standard visual inspection techniques include:

- Direct Visual Inspection: Observing the material surface for visible defects.

- Use of Magnifying Tools: Employing magnifying glasses or borescopes to enhance visibility.

- Lighting Techniques: Utilizing appropriate lighting to highlight surface irregularities.

These techniques help inspectors identify potential issues early in the manufacturing process, reducing the risk of defects in finished products.

How Does Visual Inspection Complement Other NDT Methods?

Visual inspection serves as a complementary method to other non-destructive testing techniques. It can help identify areas that require further examination using more advanced methods, such as ultrasonic or radiographic testing. By integrating visual inspection with other NDT methods, organizations can enhance their overall quality control processes and ensure comprehensive evaluations of material integrity.

How Materials Metric Supports Your NDT Needs

At Materials Metric, we understand the critical importance of accurate and reliable non-destructive testing. Our team of certified experts provides comprehensive NDT services, from initial consultation and method selection to advanced testing and compliance support. We partner with industries worldwide to ensure material integrity, enhance product safety, and streamline quality control processes.

Our Specialized NDT Services Include:

- Expert NDT Consulting: Guidance on selecting the most effective NDT methods for your specific applications. Consult US.

- Advanced Testing Solutions: Utilizing state-of-the-art equipment for ultrasonic, radiographic, magnetic particle, and eddy current testing. Explore our services

- Compliance & Standards Adherence: Ensuring your operations meet stringent industry standards like ASTM and ISO. Get compliance help

Contact Materials Metric Today

Ready to enhance your material testing capabilities?

Which Industry Standards and Certifications Govern Non-Destructive Testing?

Non-destructive testing is governed by various industry standards and certifications that ensure compliance and quality. These standards provide guidelines for testing procedures, equipment, and personnel qualifications.

What Are Key ASTM and ISO Standards for NDT Compliance?

Key standards for non-destructive testing include:

- ASTM E1444: Standard Practice for Magnetic Particle Testing. (View Standard )

- ASTM E1417: Standard Practice for Liquid Penetrant Testing. (View Standard )

- ISO 9712: Non-destructive testing — Qualification and certification of NDT personnel. (View Standard )

Materials Metric actively helps organizations navigate these complex standards, offering compliance consulting and testing services to ensure your operations meet all necessary regulatory requirements.

How Do Regulatory Requirements Impact Pharma and Medical Device Testing?

Regulatory requirements play a crucial role in non-destructive testing within the pharmaceutical and medical device industries. Compliance with standards such as ISO 13485 ensures that products meet safety and quality requirements. Failure to adhere to these regulations can result in significant consequences, including product recalls and legal liabilities. Therefore, understanding and implementing these standards is essential for organizations operating in these high-stakes sectors.

What Case Studies Demonstrate NDT Effectiveness in Pharma and Medical Devices?

Case studies provide valuable insights into the effectiveness of non-destructive testing methods in real-world applications. These examples highlight how NDT contributes to quality control and compliance in critical industries.

How Has Ultrasonic Testing Improved Quality Control in Pharmaceuticals?

In the pharmaceutical industry, ultrasonic testing has been instrumental in ensuring the integrity of drug packaging. A case study demonstrated that ultrasonic testing effectively identified micro-cracks in packaging materials, which could compromise product sterility. By implementing UT, the company significantly reduced the risk of contamination and improved overall product safety.

What Are Examples of Radiographic Inspection in Medical Device Manufacturing?

Radiographic inspection has proven essential in the manufacturing of medical devices, particularly in assessing weld integrity. A notable case involved the inspection of surgical instruments, where radiographic techniques successfully identified internal defects that could lead to instrument failure. This proactive approach not only enhanced product reliability but also ensured compliance with stringent regulatory standards.

This table illustrates the diverse applications of non-destructive testing methods and their significant impact on industry standards and safety.

| NDT Method | Application | Industry Impact |

|---|---|---|

| Ultrasonic Testing | Drug packaging integrity | Reduced contamination risk |

| Radiographic Inspection | Weld integrity in medical devices | Enhanced product reliability |

| Magnetic Particle Testing | Surface defect detection in components | Improved safety in manufacturing |

Partner with Materials Metric for NDT Excellence

Whether you need expert consultation, advanced testing, or comprehensive training, Materials Metric is your trusted partner in non-destructive material testing. Ensure the integrity and safety of your products with our industry-leading solutions.