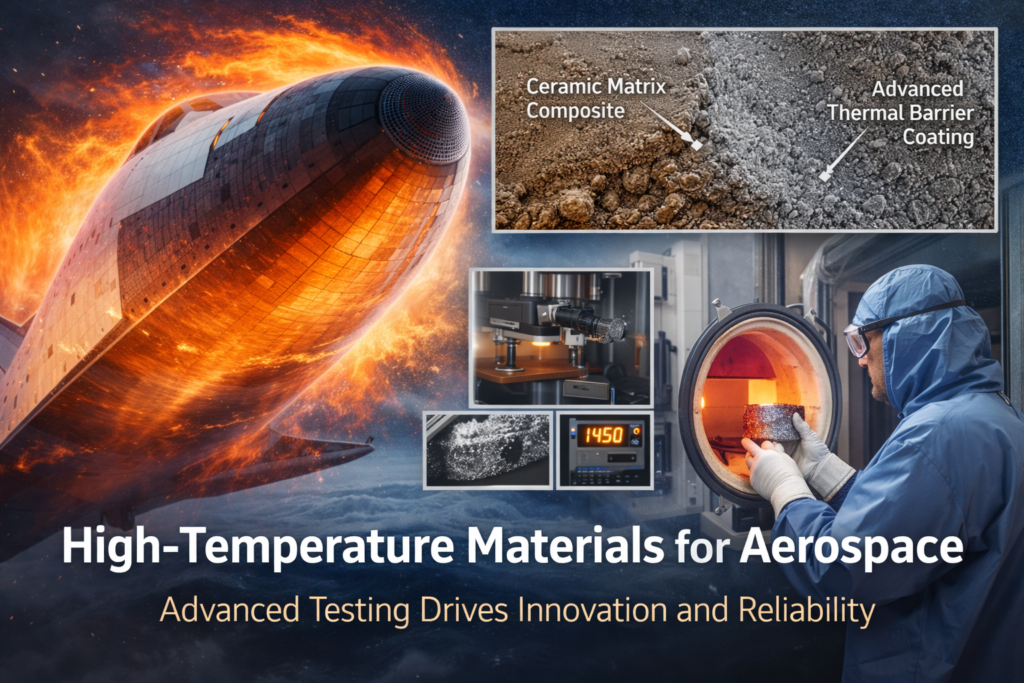

Aerospace materials operate under some of the most extreme conditions encountered in engineering. High temperatures, thermal cycling, oxidative environments, and mechanical stress demand materials that perform reliably where failure is not an option.

Advancing high-temperature materials requires not only novel material systems but also custom testing strategies that reflect real operating conditions.

Challenges in High-Temperature Aerospace Materials

Modern aerospace systems rely on materials that must:

Maintain structural integrity at elevated temperatures

Resist thermal degradation and oxidation

Perform under sustained mechanical and thermal loading

Meet strict safety and reliability standards

These requirements drive innovation in polymers, composites, ceramics, and protective coatings.

Emerging High-Temperature Material Systems

Key areas of research include:

High-performance polymers and polymer matrix composites

Ceramic and ceramic-matrix composites for thermal protection

Advanced coatings for heat, oxidation, and corrosion resistance

Additively manufactured components with complex microstructures

Each material system introduces unique testing challenges that standard methods often fail to address.

How Materials Metric Supports Aerospace Materials Development

Materials Metric delivers custom testing solutions tailored to high-temperature aerospace applications, including:

Thermal stability and degradation analysis at elevated temperatures

Mechanical and structural characterization under extreme conditions

Surface and interfacial analysis of coatings and composites

Our testing protocols are designed around application-specific requirements, ensuring meaningful and actionable data.