Before any new material, medical device, or drug reaches patients or consumers, it must pass one crucial gate: preclinical testing. This stage serves as the bridge between scientific discovery and real-world application, ensuring that innovation does not come at the cost of safety or efficacy.

At Materials Metric, we often describe preclinical testing as the “stress test” for innovation. It’s where ideas are validated, performance is quantified, and potential risks are identified long before products reach the market.

Here’s why it matters:

1. Safety Before Scale

Preclinical studies reveal how materials and formulations behave under realistic biological and environmental conditions. From biocompatibility and cytotoxicity to chemical stability and degradation, these tests help determine whether a product is safe for use in humans or the environment.

2. Regulatory Readiness

FDA, ISO, and ASTM standards require thorough preclinical evaluation. Early testing aligned with these standards not only accelerates regulatory approval but also minimizes costly redesigns or delays later in development.

3. Data-Driven Design Decisions

By analyzing performance data—mechanical strength, surface characteristics, leachables, and degradation patterns—engineers and scientists can refine formulations and processes before committing to large-scale manufacturing.

4. Reducing Failure Risk

A well-designed preclinical testing strategy helps identify potential points of failure early on. Whether it’s a coating that delaminates under stress or a polymer that triggers unexpected biological responses, discovering these issues in the lab prevents far greater losses in clinical or market stages.

5. Building Trust and Transparency

In today’s innovation landscape, transparency in testing and validation isn’t just regulatory, it’s reputational. Preclinical data gives investors, partners, and end users confidence that your product stands up to scientific scrutiny.

At Materials Metric, we combine advanced materials characterization, chemical and analytical testing, and biocompatibility studies to create a comprehensive preclinical roadmap. Our ISO 9001:2015–driven processes ensure precision, reproducibility, and compliance at every step, helping innovators bring safe, high-performance products to market faster.

From concept to compliance, preclinical testing is where innovation earns its credibility.

At Materials Metric, we understand that every innovation is unique and so are its testing needs. Our integrated preclinical testing platform combines state-of-the-art instrumentation with regulatory insight to deliver results you can trust.

-

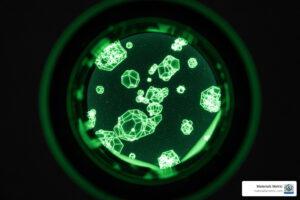

Advanced Microscopy & Surface Analysis: Visualize microstructural integrity, surface roughness, and coating adhesion at nanoscale resolution.

-

Mechanical & Biomechanical Testing: Assess durability, fatigue, and fracture resistance of materials under real-world loading conditions.

-

Chemical & Elemental Characterization: Identify composition, impurities, and degradation products through spectroscopy, chromatography, and trace metal analysis.

-

Biocompatibility & Toxicity Testing: Evaluate cytotoxicity, sensitization, irritation, and hemocompatibility to ensure compliance with ISO 10993 standards.

-

Extractables & Leachables Studies: Quantify potential contaminants to meet FDA and ISO regulatory expectations for safety.

Each study is conducted under ISO 9001:2015–certified quality systems and guided by Good Laboratory Practices (GLP)–aligned SOPs, ensuring every data point stands up to scientific and regulatory scrutiny.

Whether you’re developing a medical device, implant, polymer, or advanced material, our team helps you design a custom testing roadmap that moves your product from concept to clinical readiness—with confidence, speed, and precision.

Materials Metric — Measure, Analyze & Innovate